Game Gear VA0 - 3

Console status

| Date | Power | Sound | RLB | Game operation | Screen |

|---|---|---|---|---|---|

| 2023/10/21 | ❌ | ❌ | ✔️ | ✔️ | ⚠️ |

| 2024/06/24 | ❌ | ❌ | ✔️ | ✔️ | ⚠️ |

Console details

- Japanese Game Gear bought during my trip to Japan on August 2023

- The screen protector was already replaced but the console seemed unmodified (screws were tight and capacitors were the stock ones)

Specs

- Model Number: HGG-3210

- Serial Number: B0097296

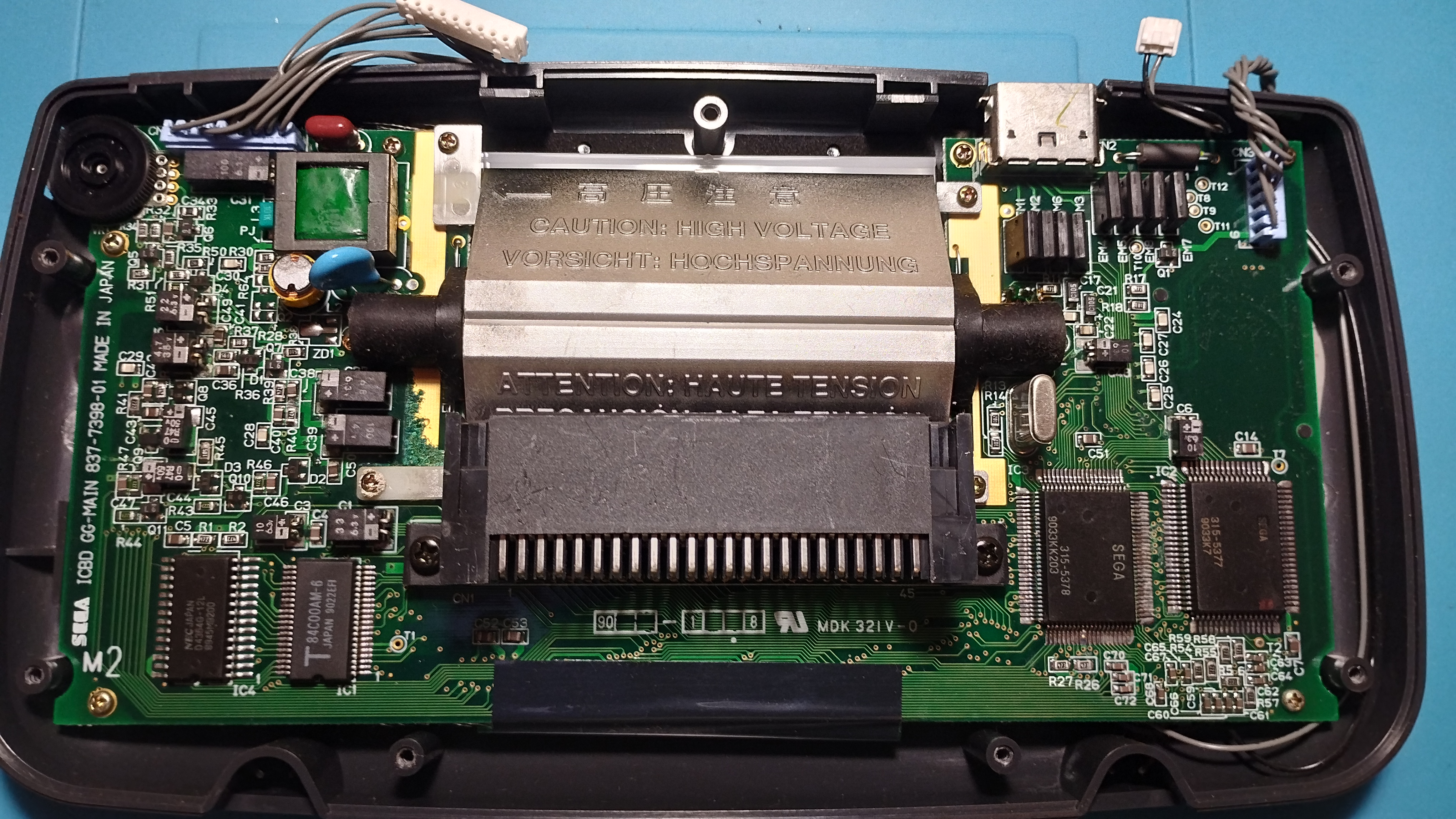

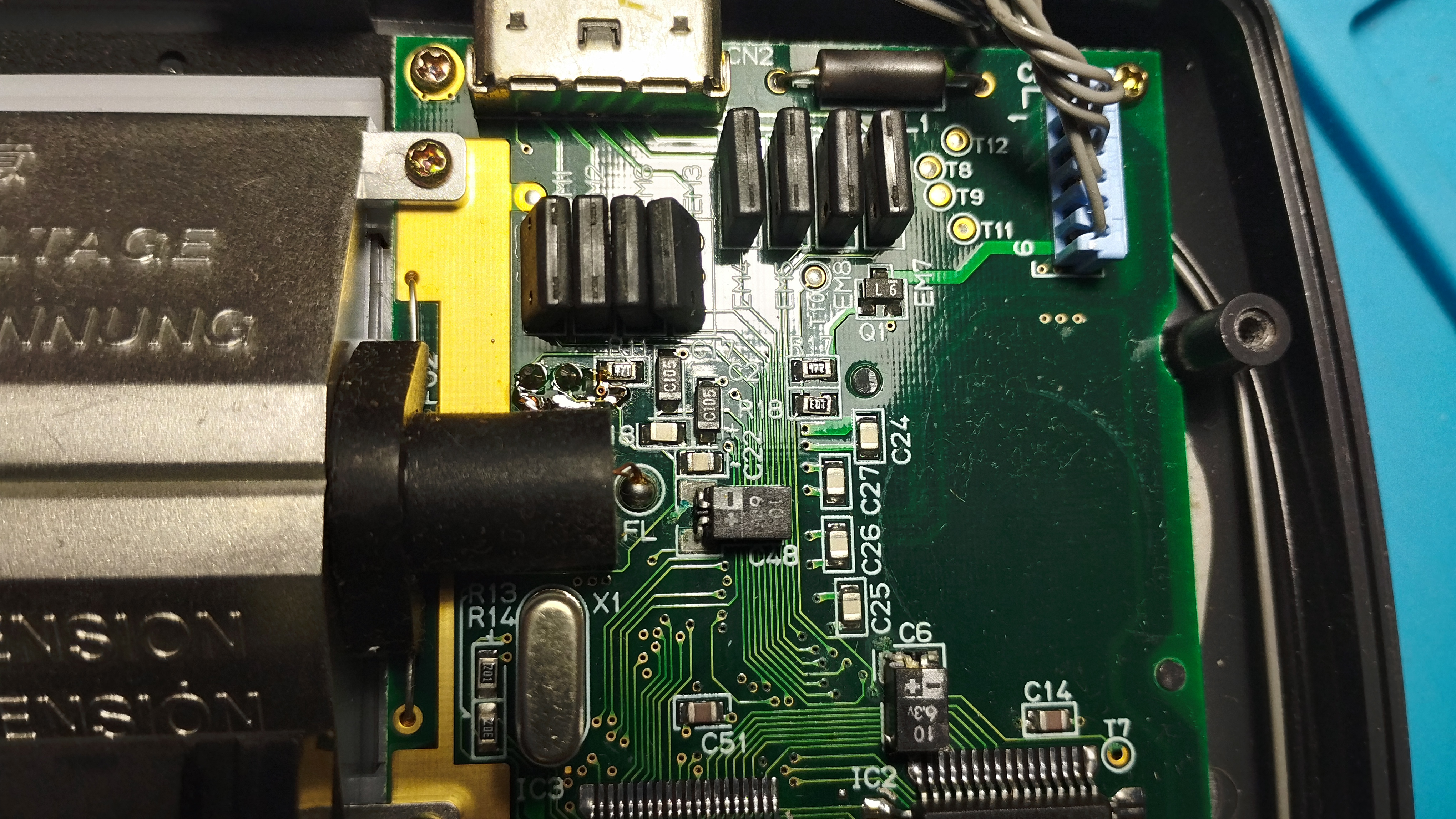

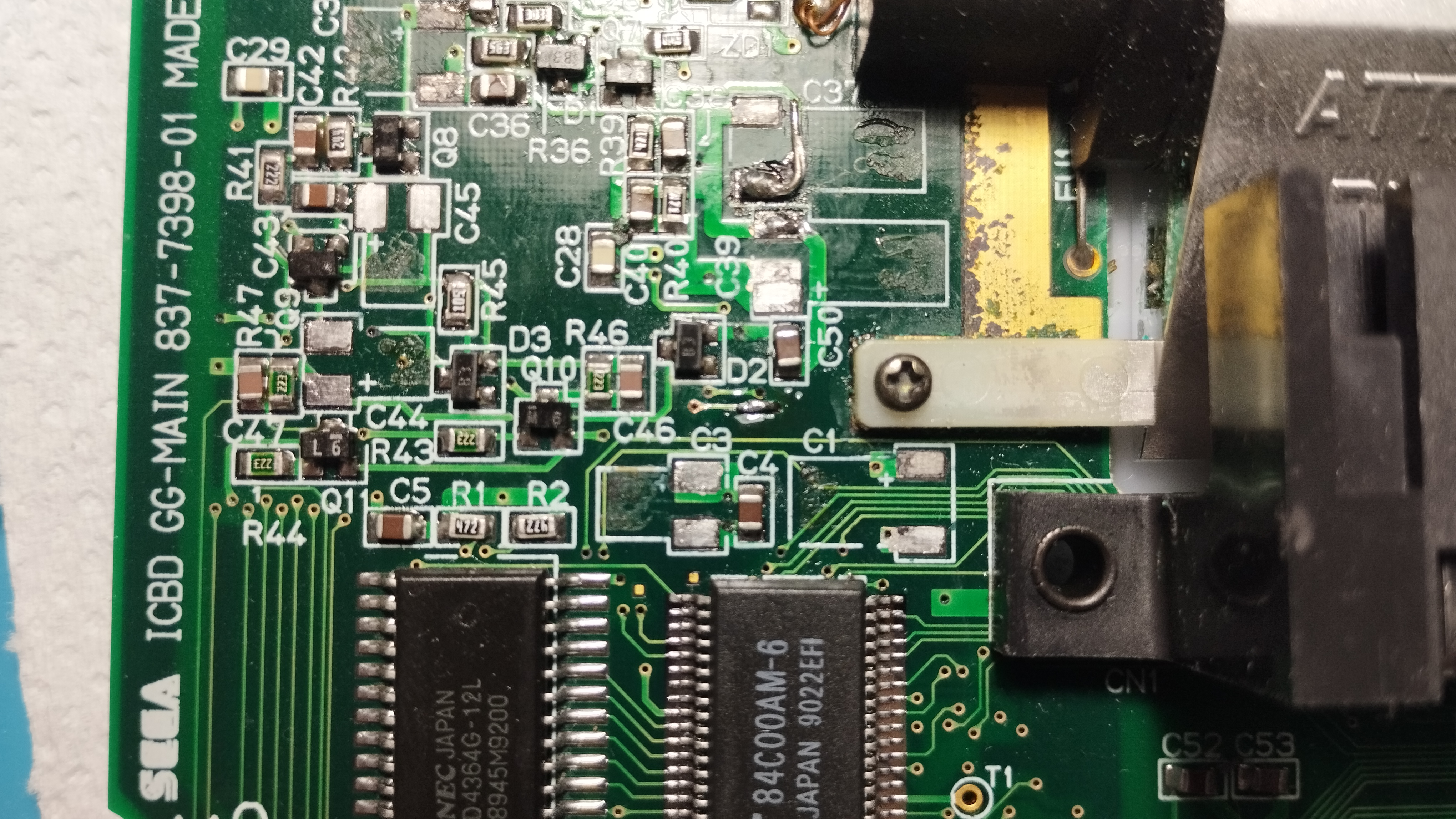

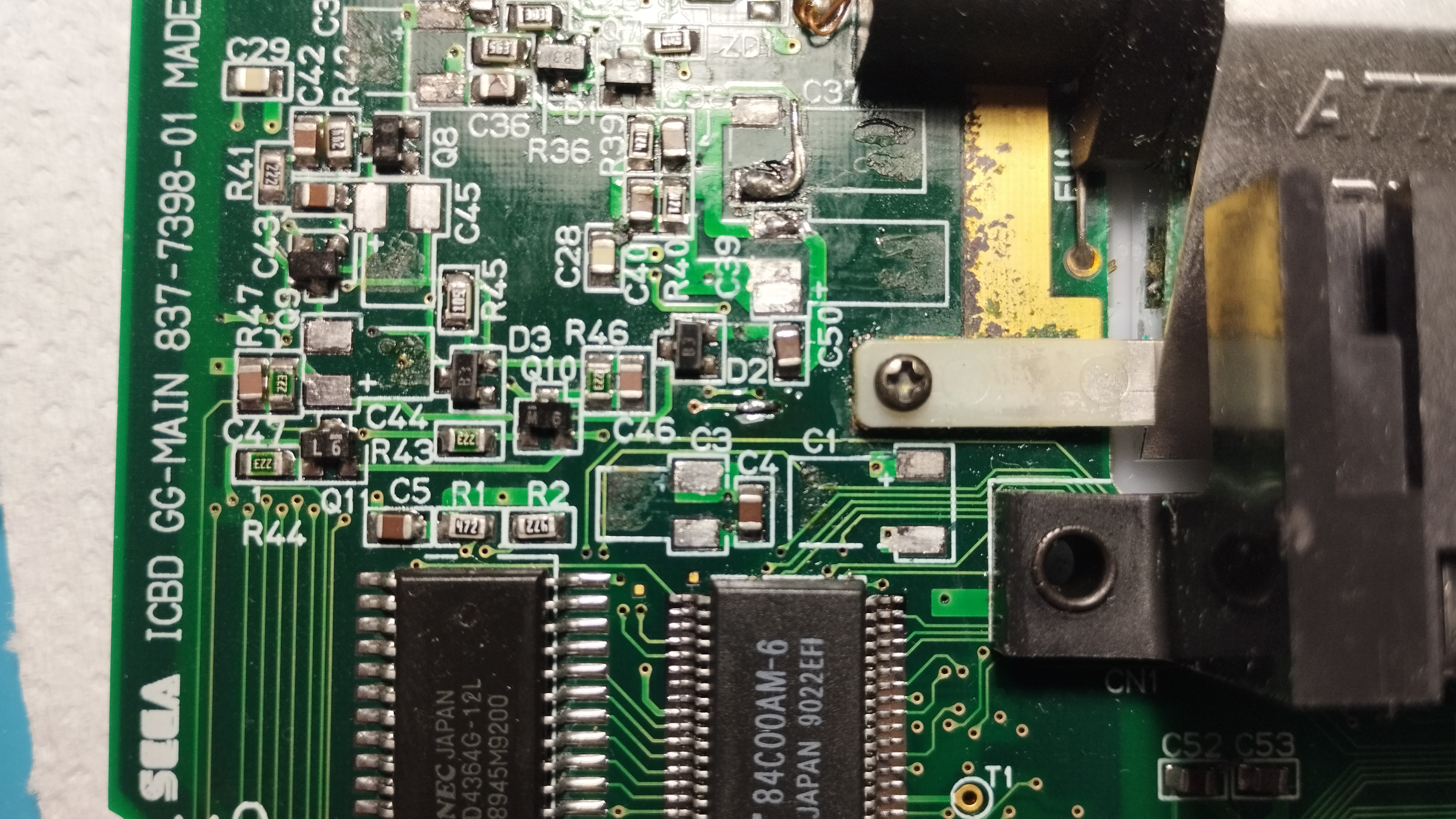

- Main board: 837-7398-01 (Twin ASIC)

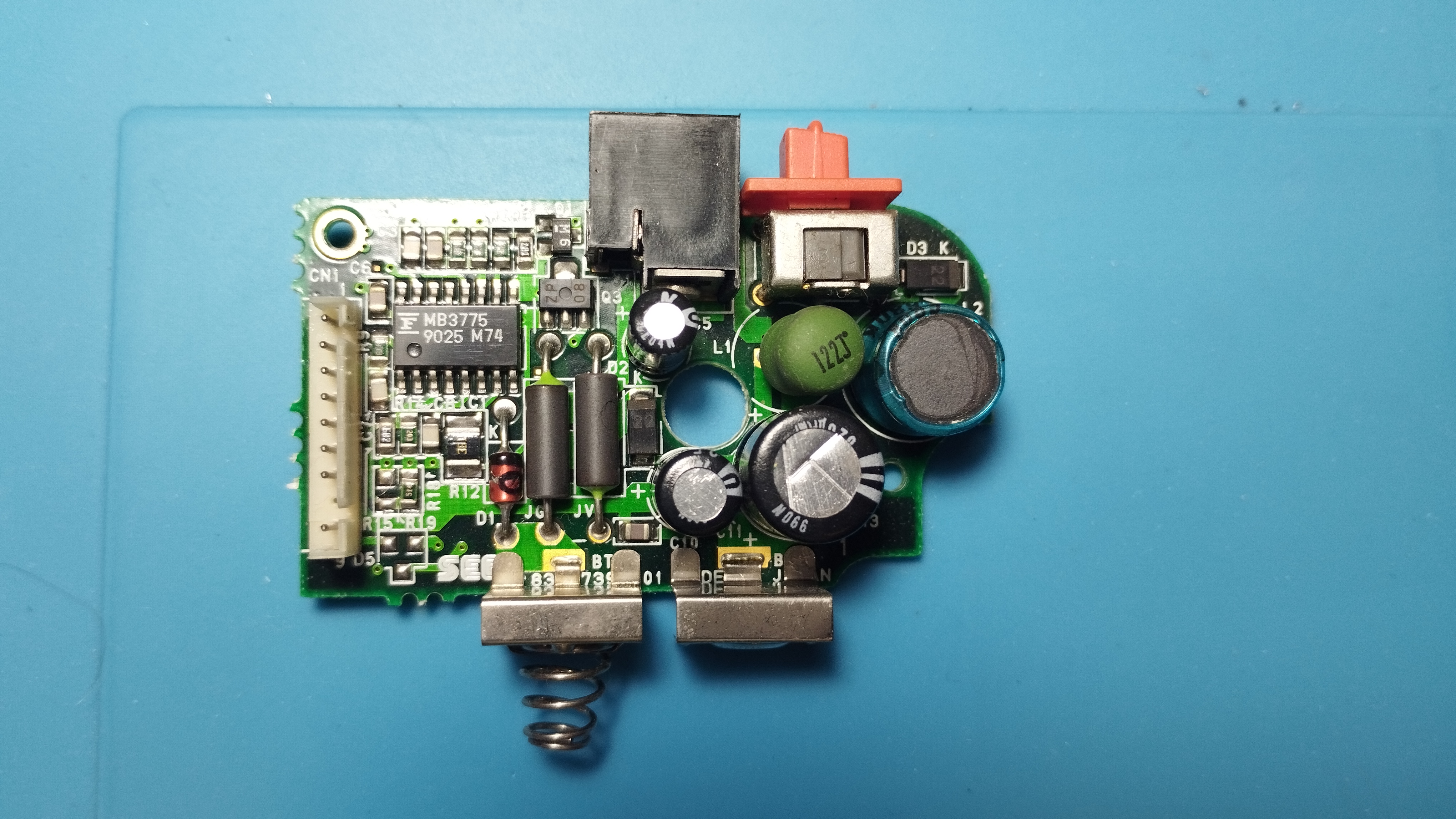

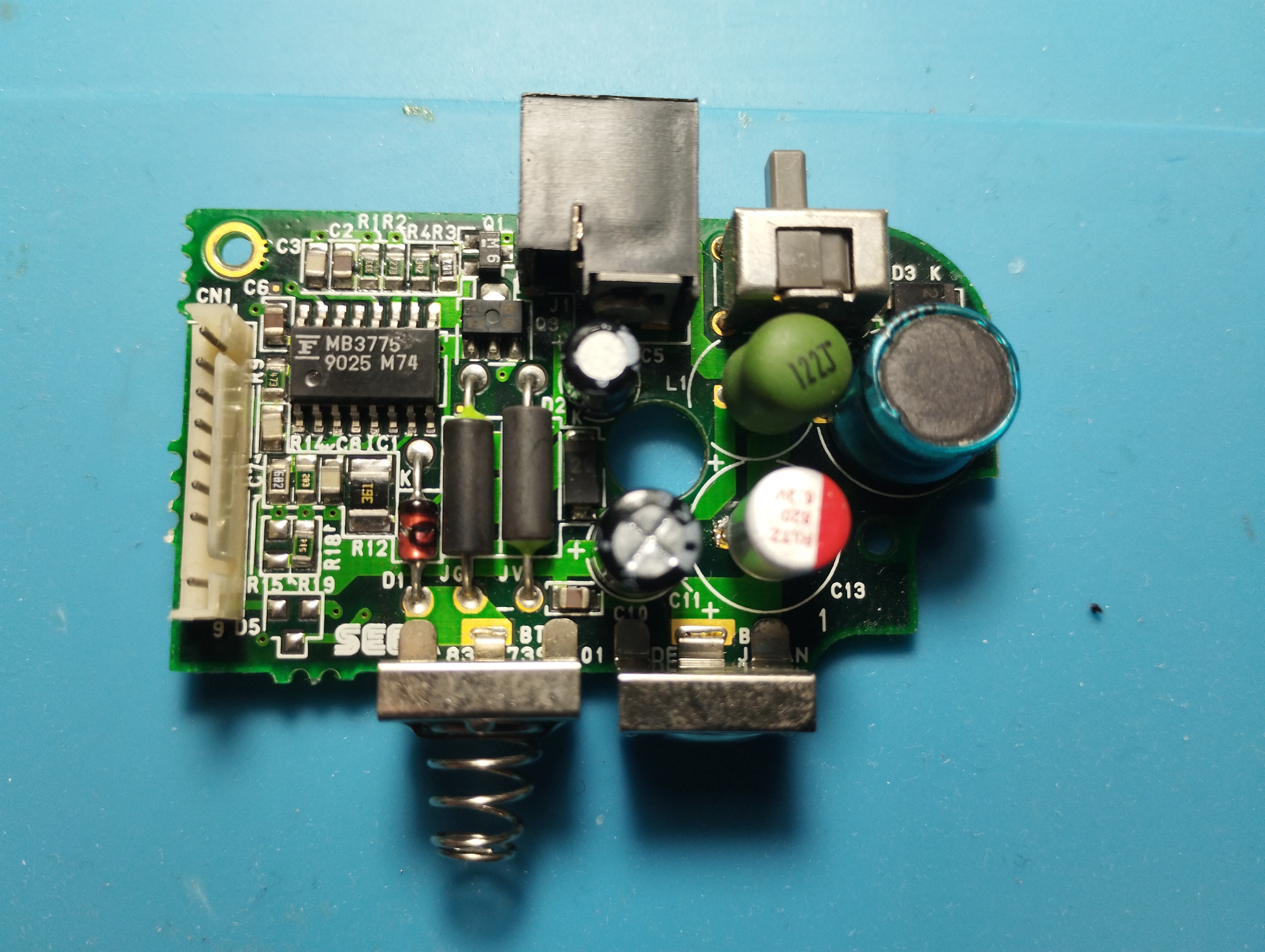

- Power board: 837-7399-01

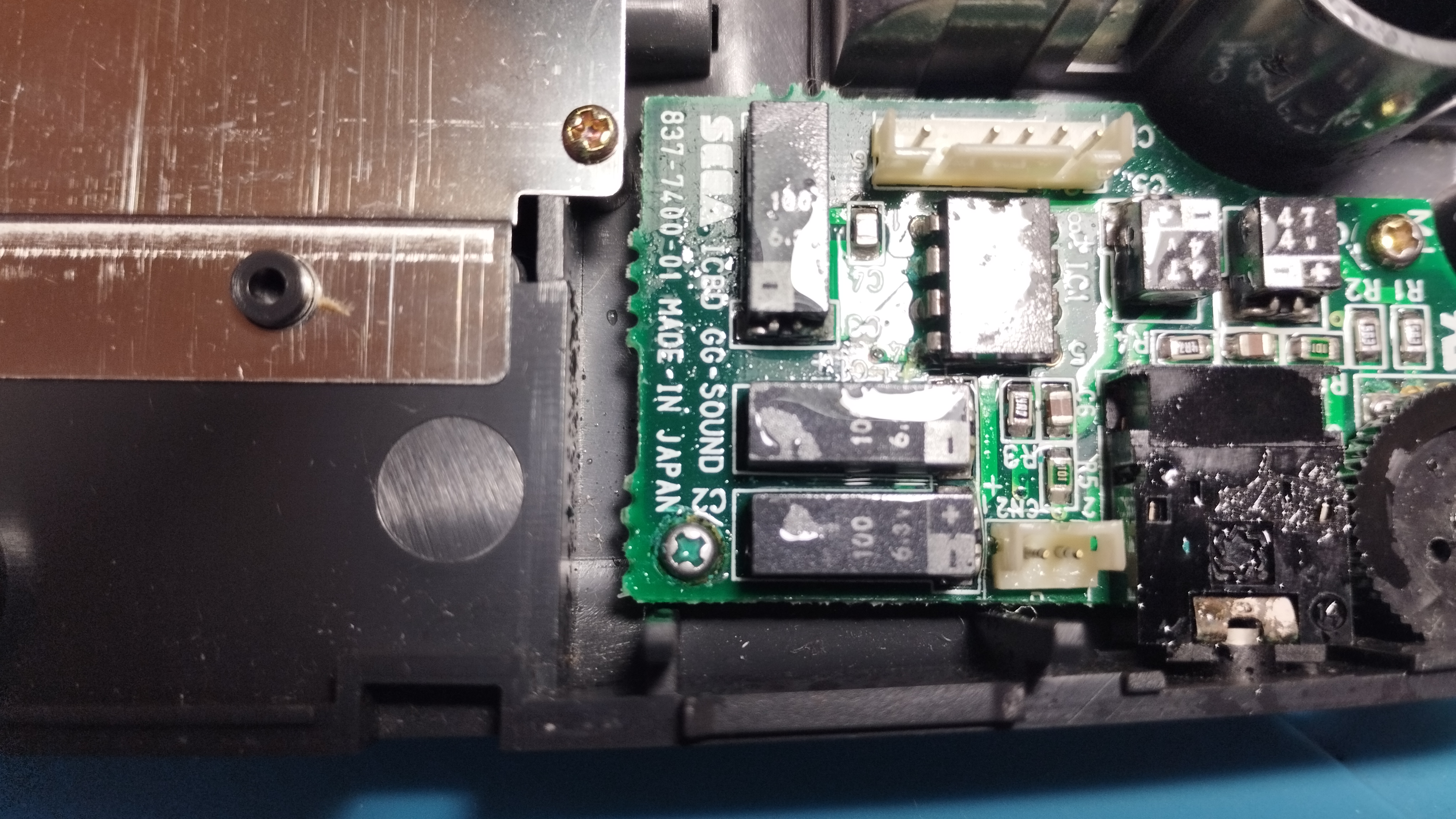

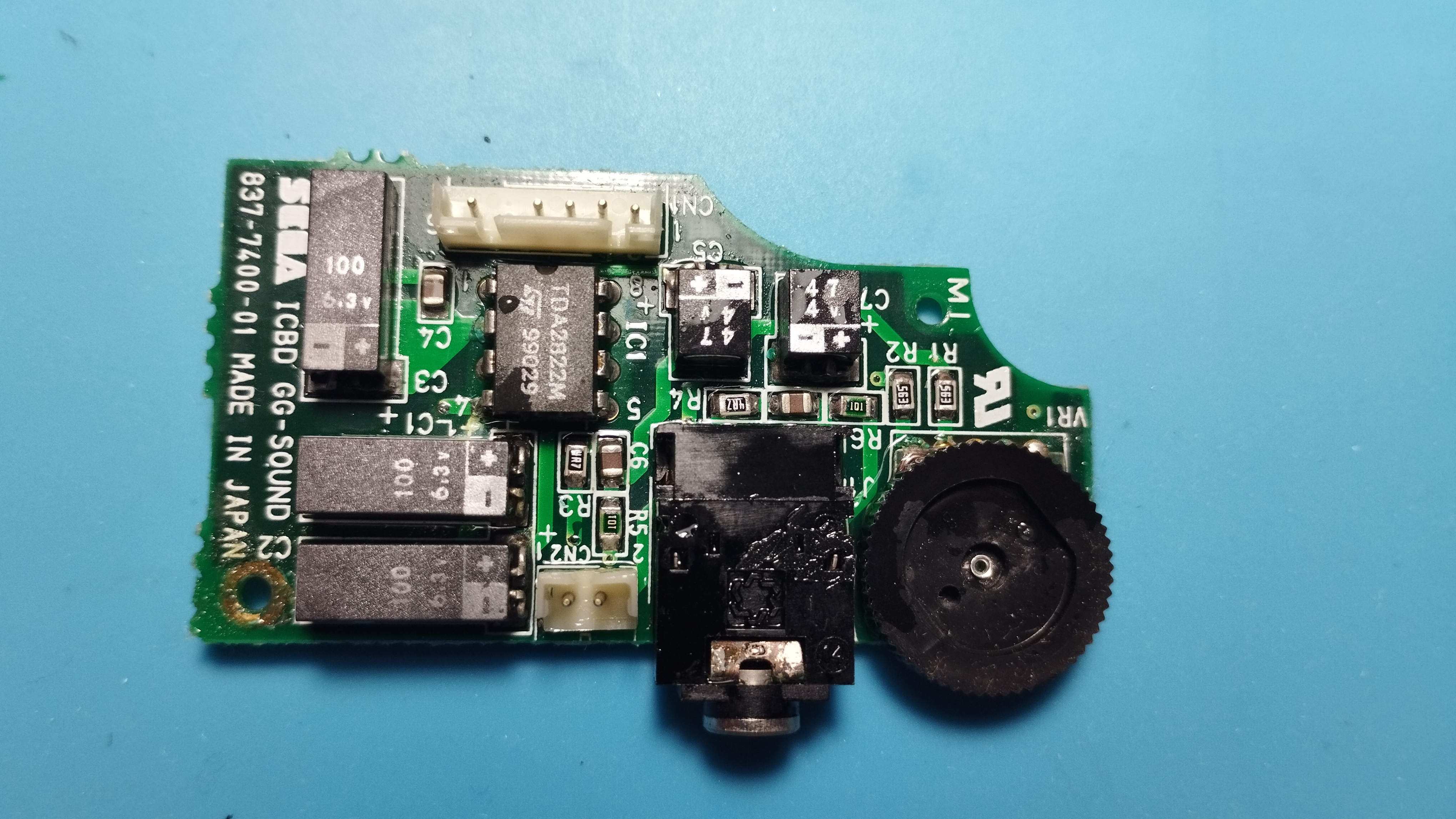

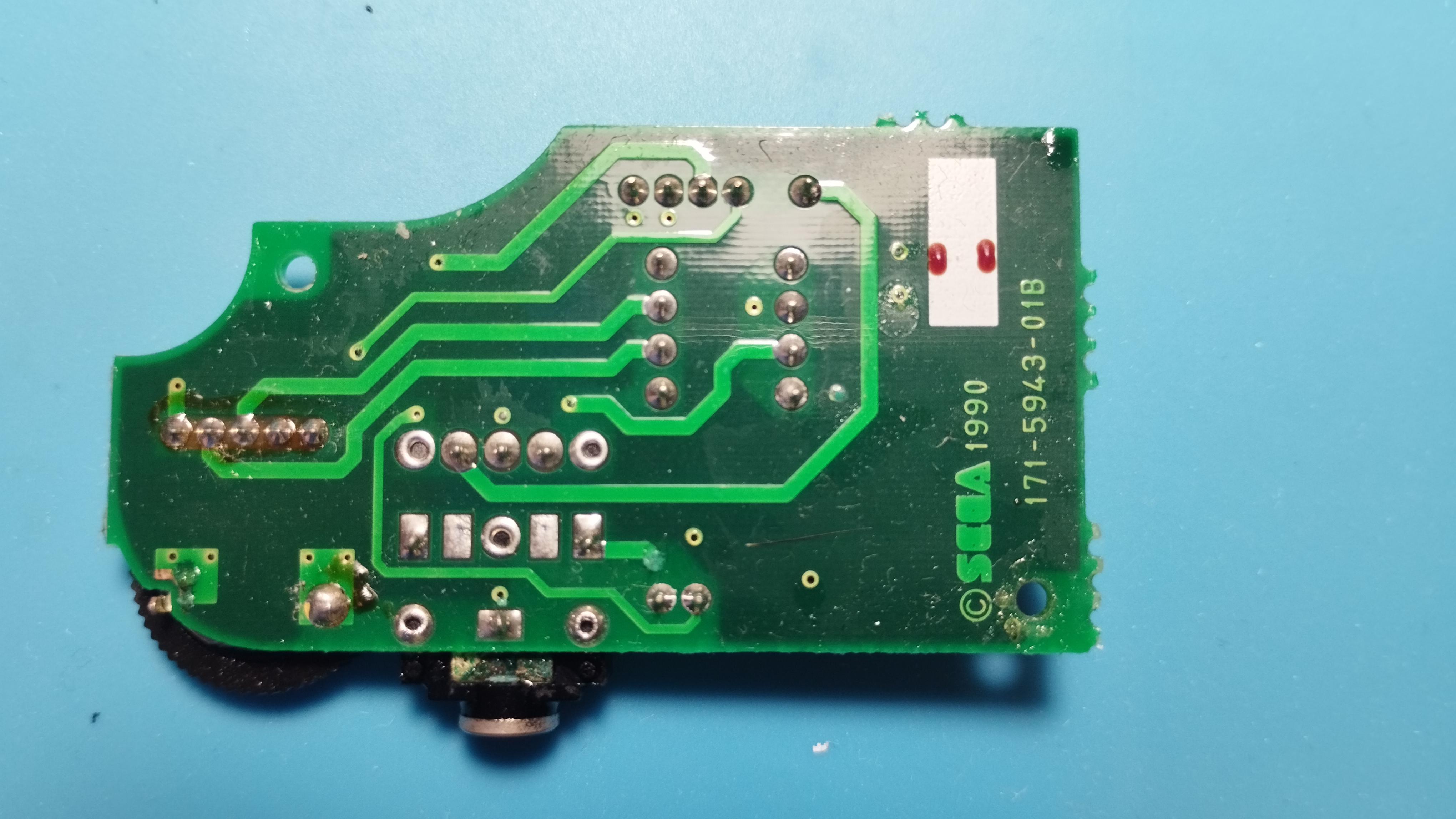

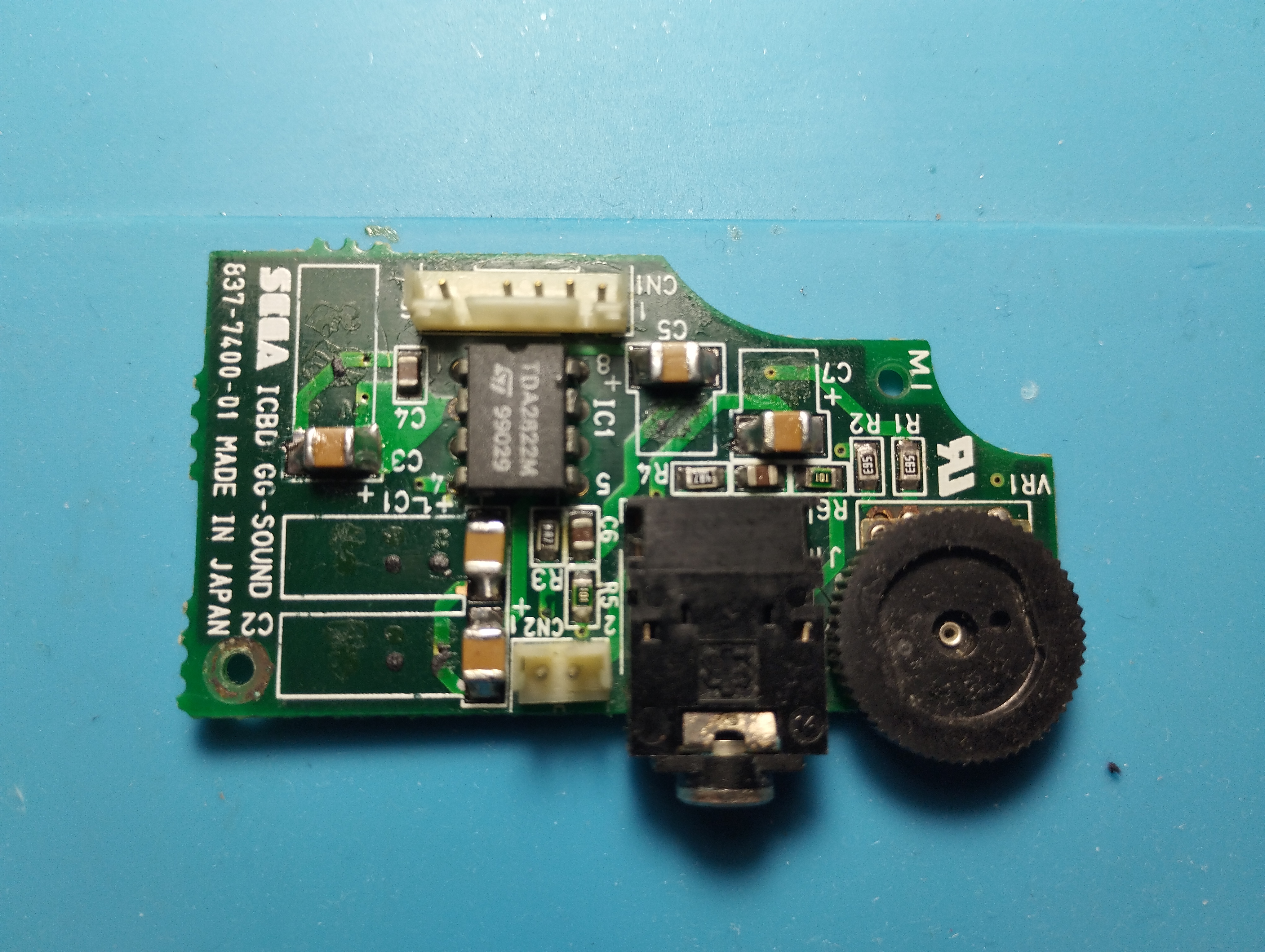

- Audio board: 837-7400-01 (Initial release Japanese Game Gear with square-body surface mount caps similar to GG main boards)

Overview

Visual inspection

- Outside: the outside has visible scratches from usage but no cracks

- Battery contacts: no signs of corrosion in the springs and plates

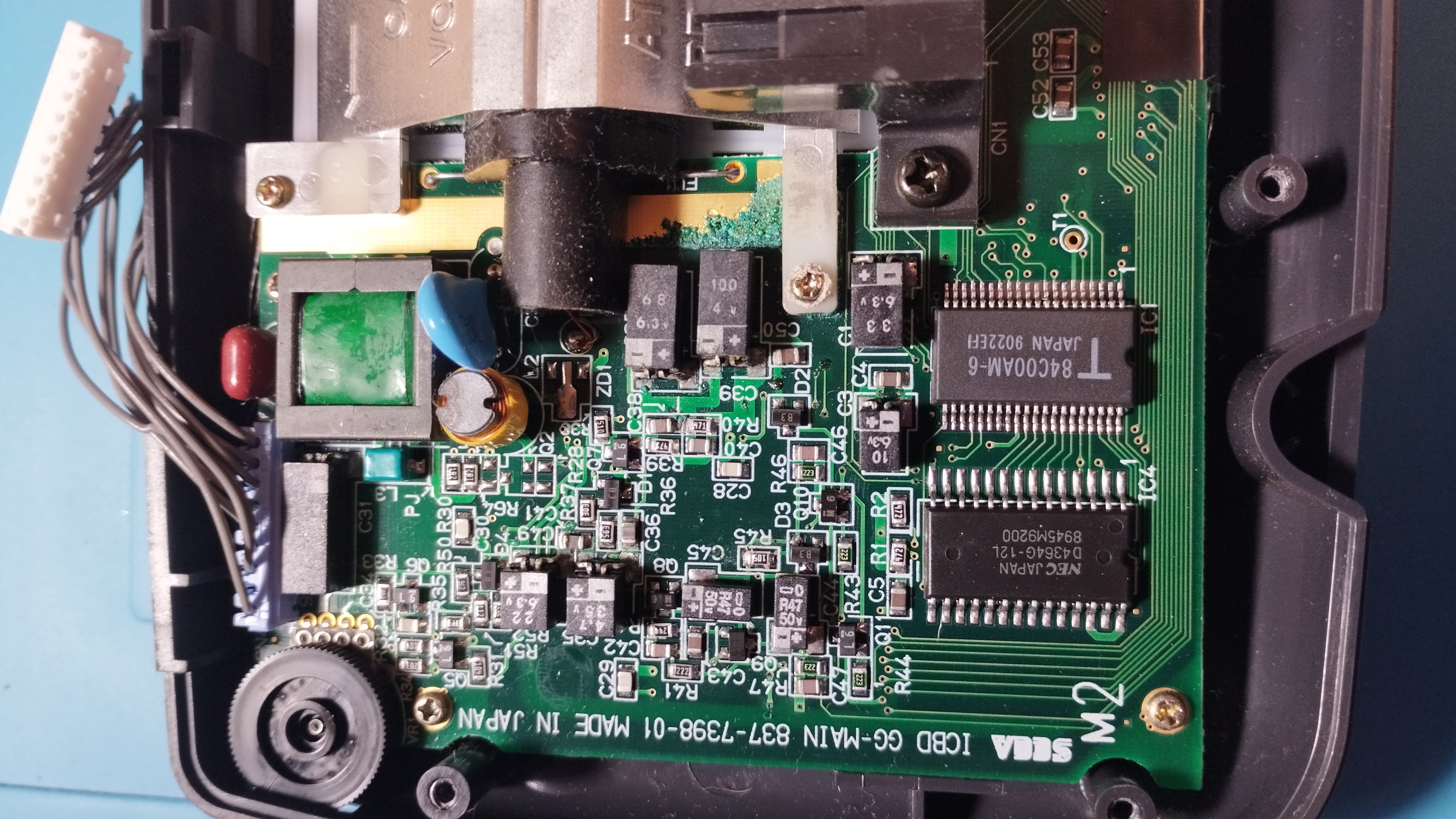

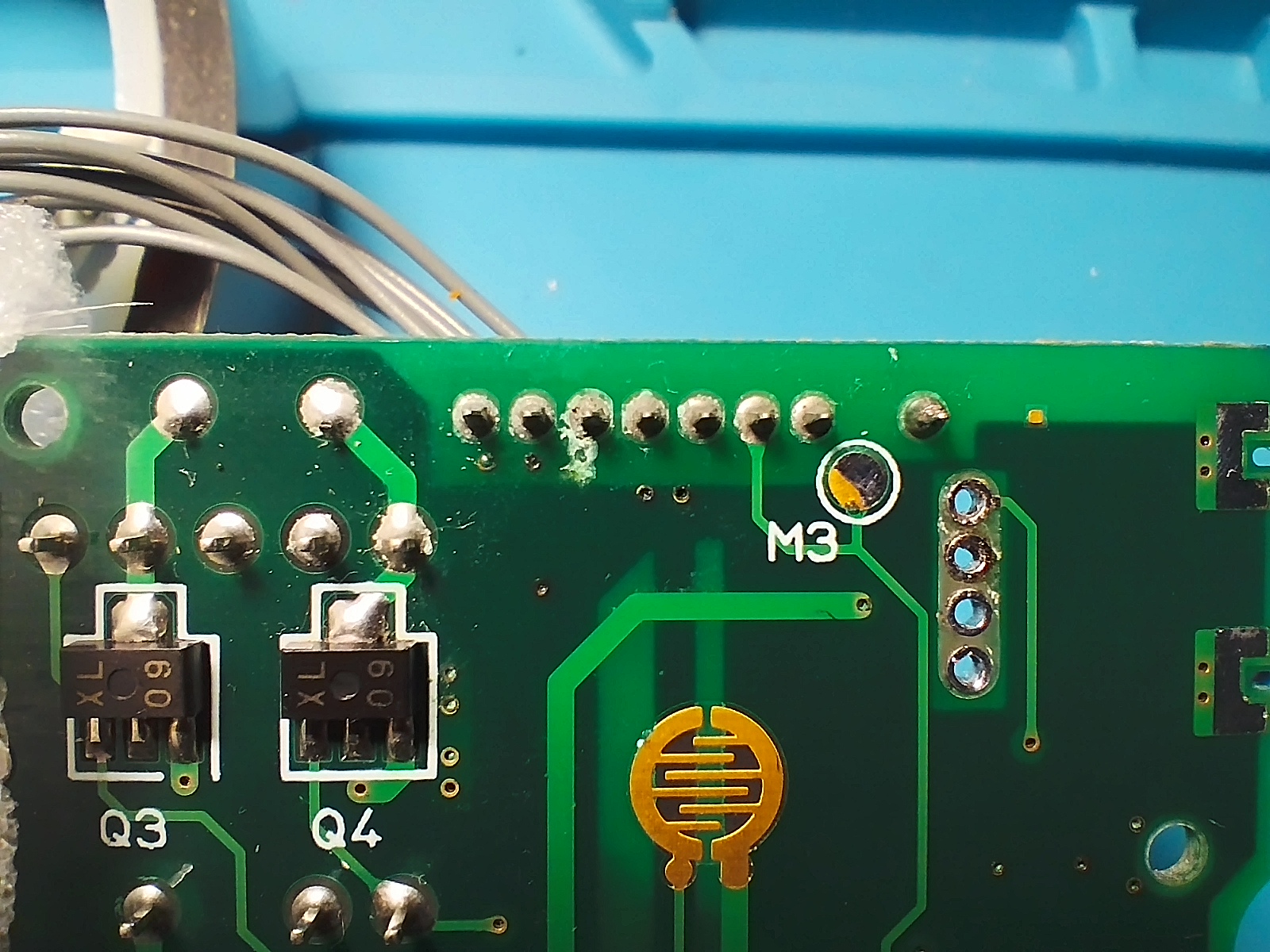

- Main board: capacitor leaks are visible on its legs, extreme precautions when removing and cleaning the pads. Also a lot of traces have been corroded, it’s possible that connectivity between layers is broken at some points

- Power board: no visible leaks

- Audio board:

First boot

- Power LED turns on a few seconds and then it turns off

- The screen doesn’t turn on and there’s no sound either

Maintenance

2023/10/21: Recap

Following Retrosix’s wiki, the capacitors are replaced like this:

Power board

- Capacitors are replaced with new electrolytic ones with the same rating

- The only exception is the 820uF/6.3V one that has been replaced with a solid electrolytic capacitor of the same rating (does it make any difference compared to the standard electrolytic ones?)

- According to the data sheet, solid electrolytic capacitors have a low ESR and high ripple current

Power board doesn’t properly provide 34V even after recapping. Using a functional audio board for the tests

Removing some capacitors proved to be quite challenging, even with an electrical desoldering pump. The trick to keep the vias intact is to reapply new solder several times to mix old solder with new one. Flux is indispensable to help transfer heat on already old and dry solder as well!

If a leg is stubbornly stuck, use some desoldering wick with new solder and a lot of flux to remove the excess inside the via by capilarity. Rinse and repeat until the leg is free!

Also use the desoldering wick to free the hole from solder before putting the new capacitors.

Audio board

- All capacitors are replaced with 100uF/10V ceramic capacitors

- C1 positive pad has been literally destroyed by corrosion. The new capacitor is soldered directly to the trace by exposing it a little bit

Audio board still not working after recap! Sound is very dim from both speaker and jack, almost imperceptible due to the static noise. Using a functional audio board for the tests

Main board

Before doing any heating work, and seeing the amount of corrosion in the zones near the capacitors, I decided to apply a generous amount of white vinegar to all of them and let it act during some minutes, while avoiding any leakage to the LCD.

This time, and following RetroSix Wiki advises, all capacitors have been first removed and then checked if the console reaches the Red Light Boot (RLB) state:

Components Needed for RLB

It’s worth noting that audio ICs, every aluminium capacitor, the LCD, MPU, Work RAM nor Video RAM or main crystal are involved or even needed to be soldered on the board to get to red light boot. Don’t waste your time on those until you get red light.

With the capacitors removed, both power board and audio board are re-connected and the console is powered up again:

- Power LED doesn’t turn on

- Fluorescent tube lights up for a few seconds and after that

- Audio doesn’t work with a cartridge on

We haven’t reached the RLB state, so further troubleshooting is required before soldering the new capacitors.

Continuity check:

- Good ground: OK, both R52 right pad and ASIC ground pad are connected to the ground plane

- Power board supply voltages: All pins are correctly connected to the pins on the Main Board and also are within the acceptable voltage ranges

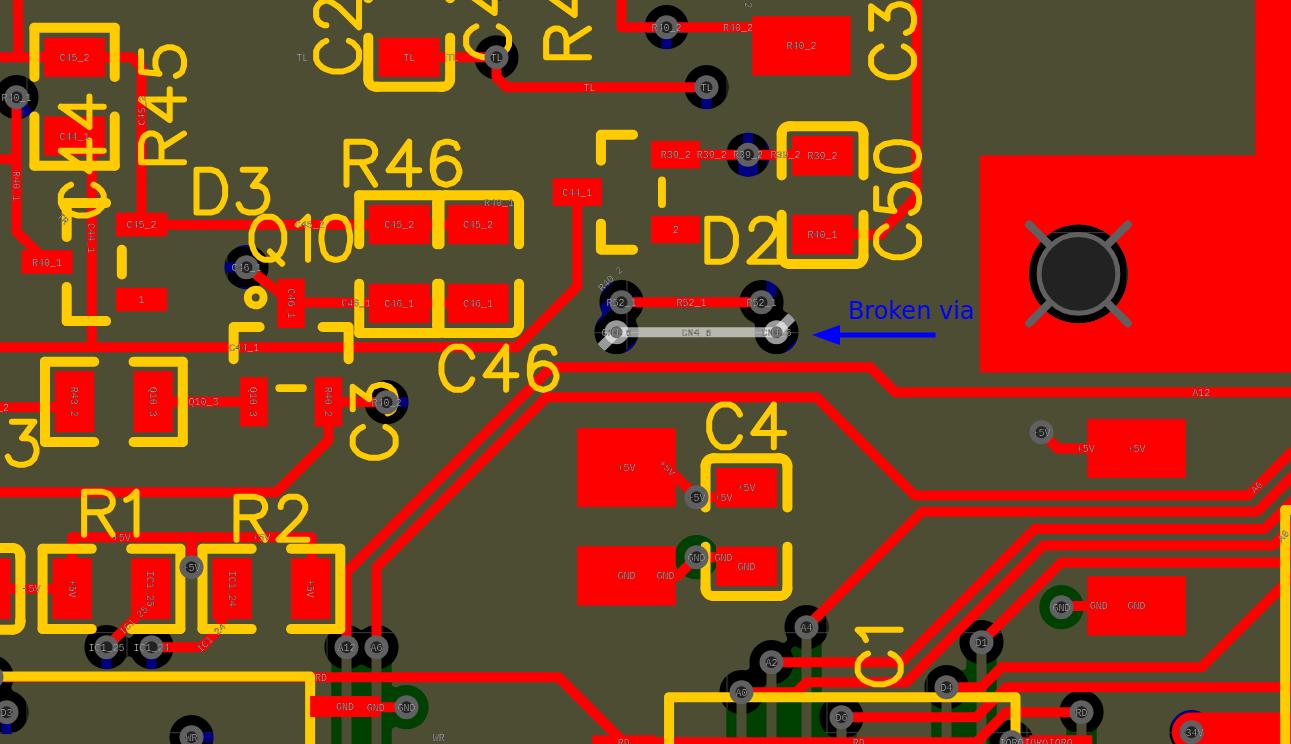

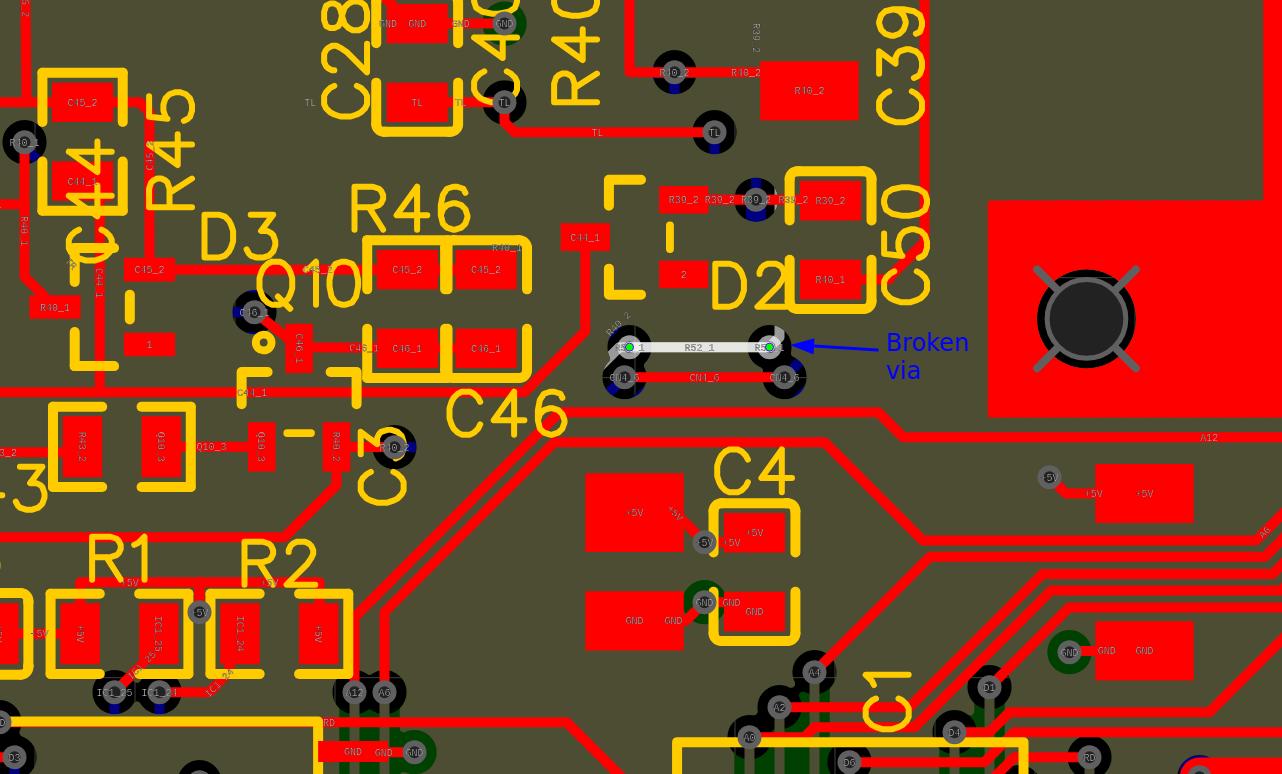

- VRef Continuity: VRef continuity to ASIC is broken:

- 1st point of discontinuity: via just below D2, connecting both layers

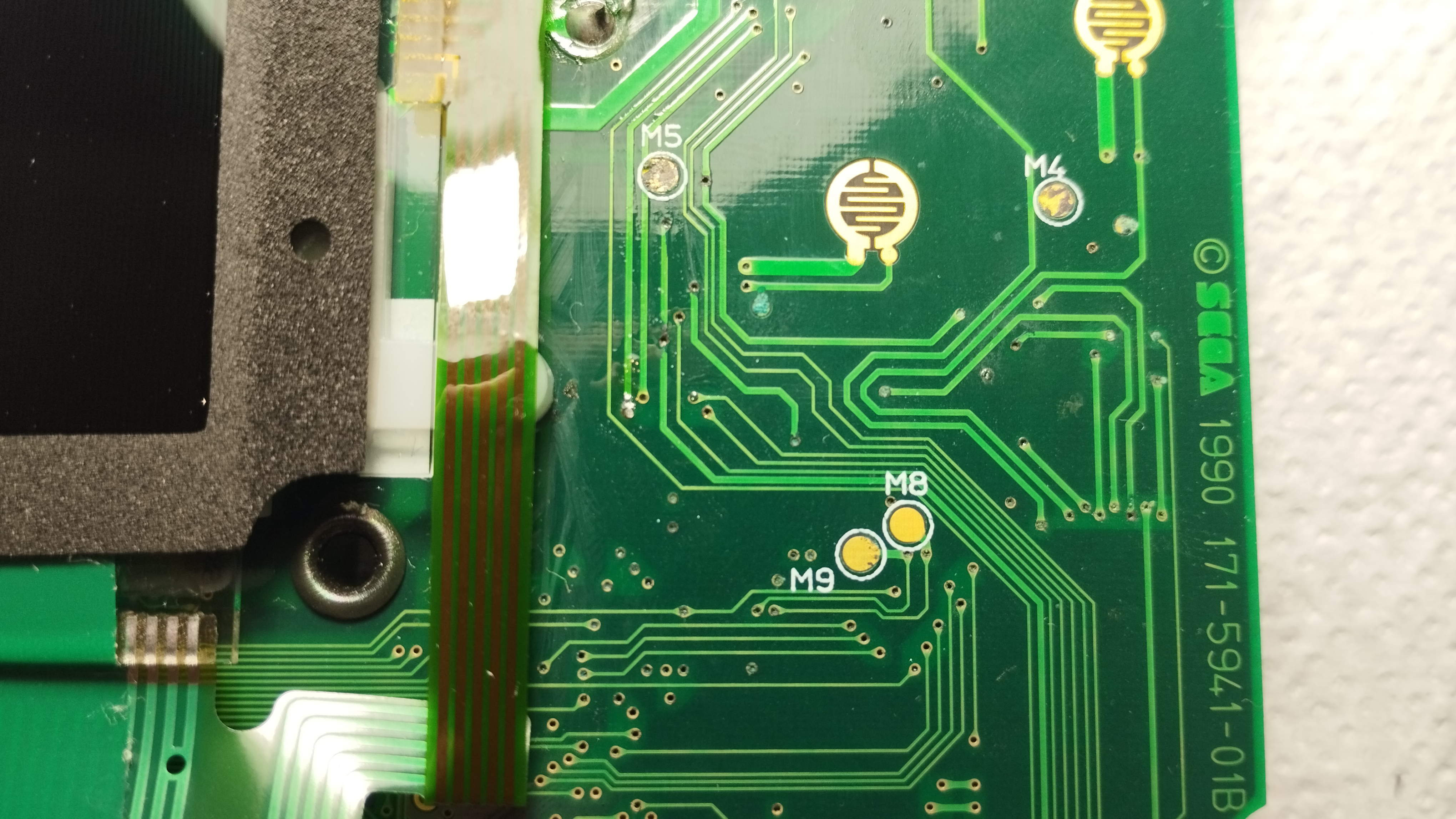

EasyEDA - 2-ASIC schematic detail. Broken VRef continuity - Fixed by drilling a small hole in the via and soldering a capacitor leg through it

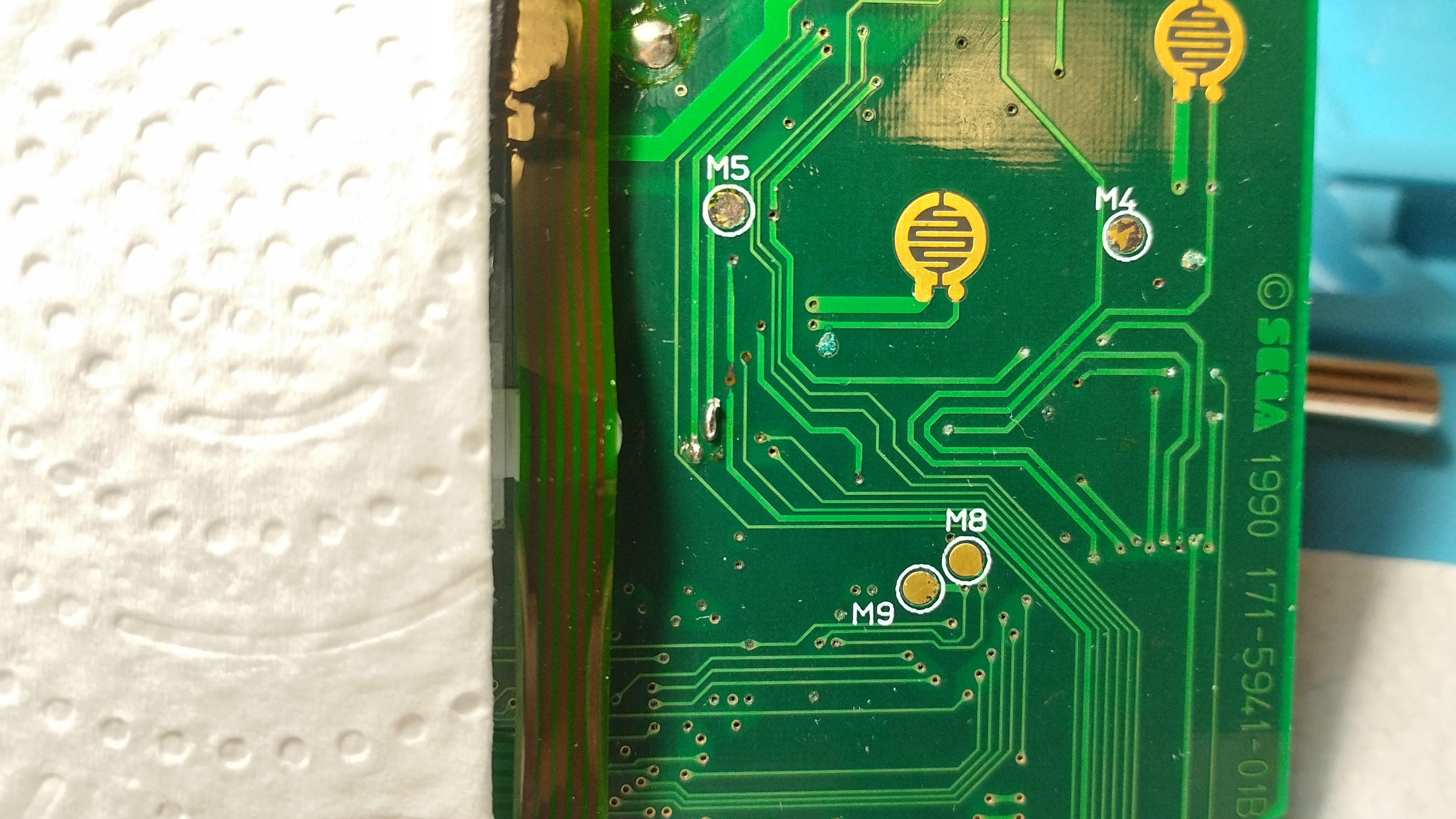

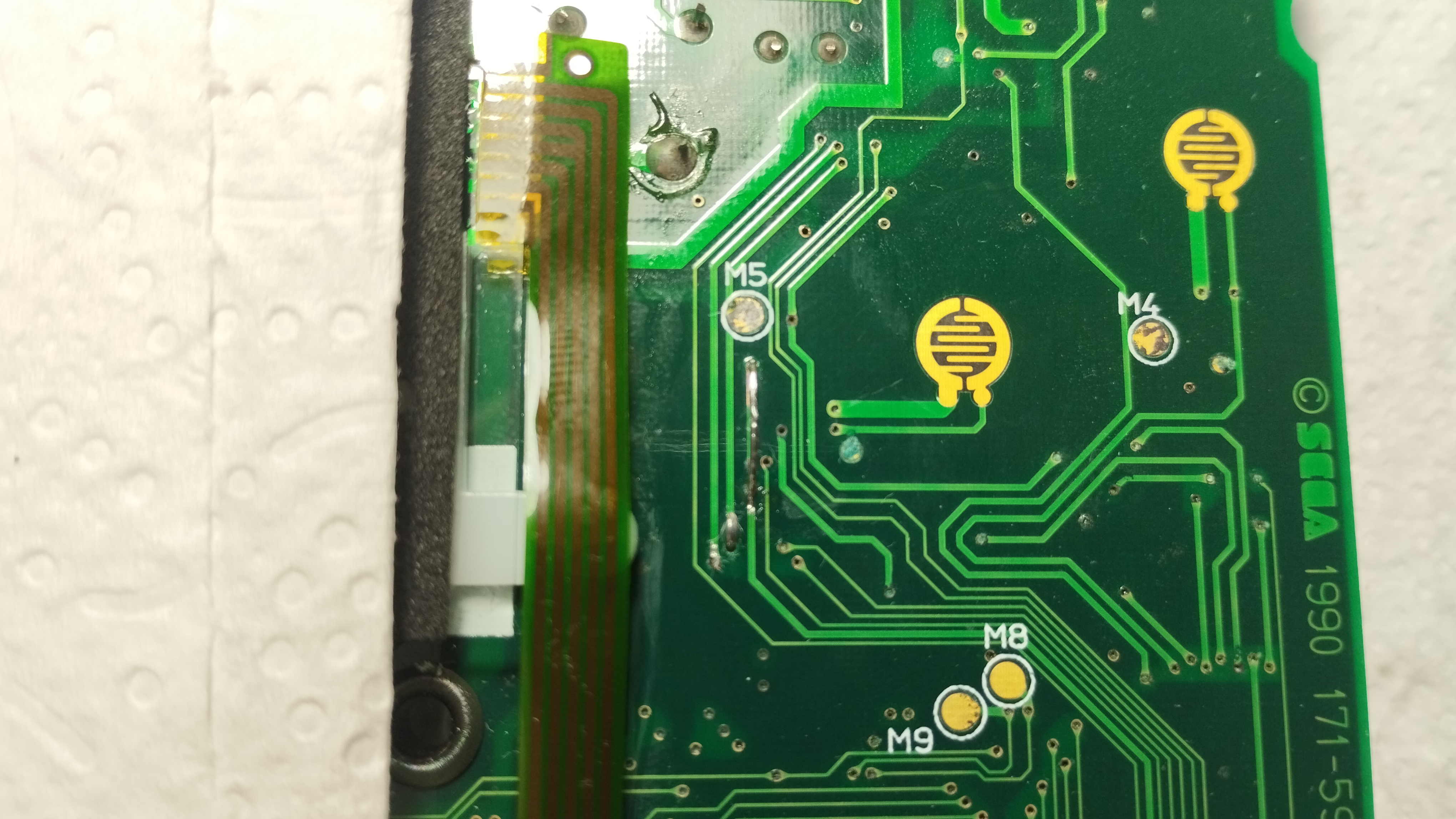

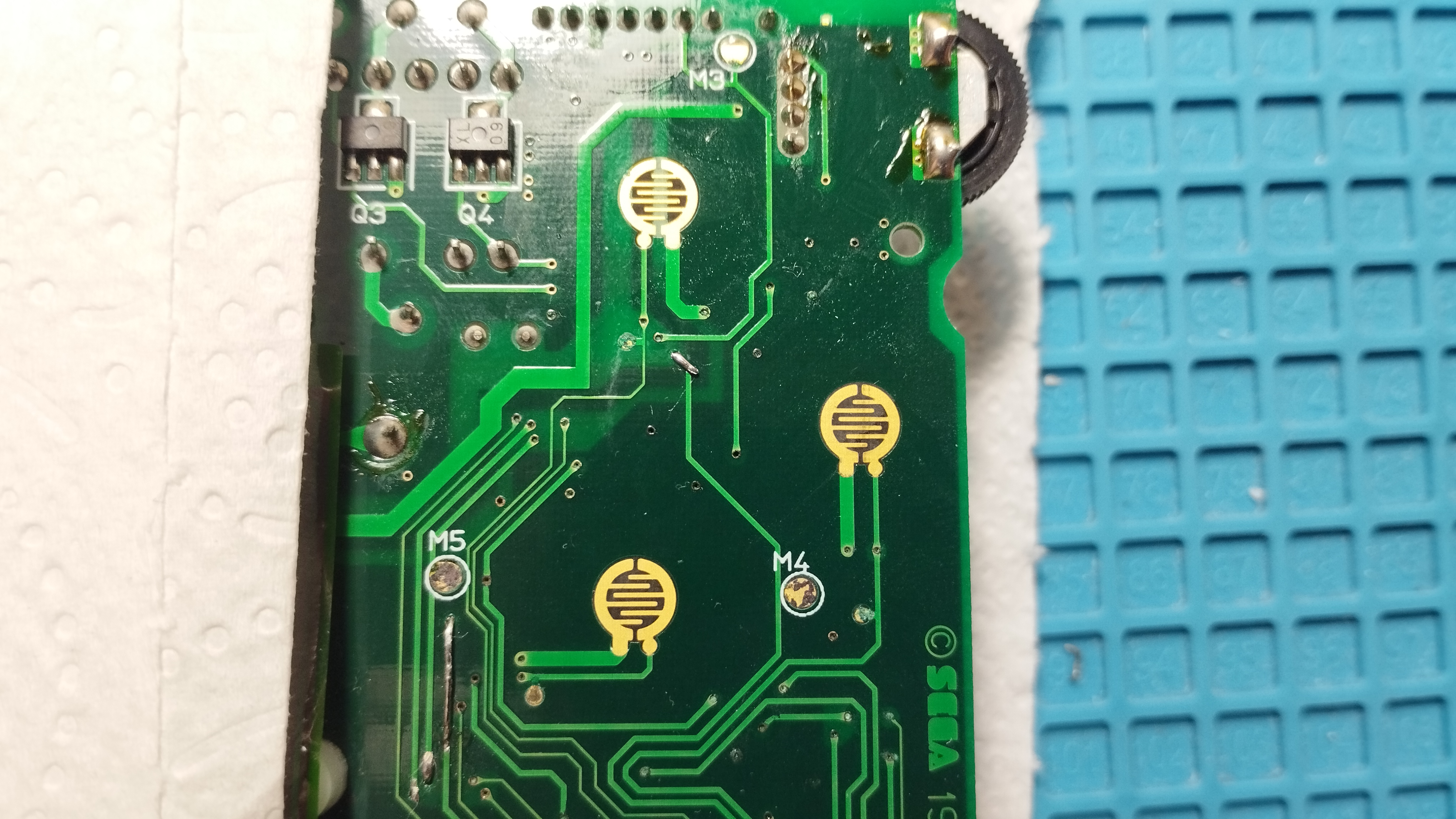

Mother Board - rear view. Fixed connectivity of VREF below D2

Mother Board - front view. Fixed connectivity of VREF below D2 - VOnOff network: VOnOff continuity to ASIC is broken:

- 1st point of discontinuity: via just below D2, connecting both layers

Mother Board - Broken connectivity of VOnOff below D2

EasyEDA - 2-ASIC schematic detail. Broken Vonoff continuity - Fixed by drilling a small hole in the via and soldering a capacitor leg through it

Mother Board - rear view. Fixed connectivity of VOnOff below D2

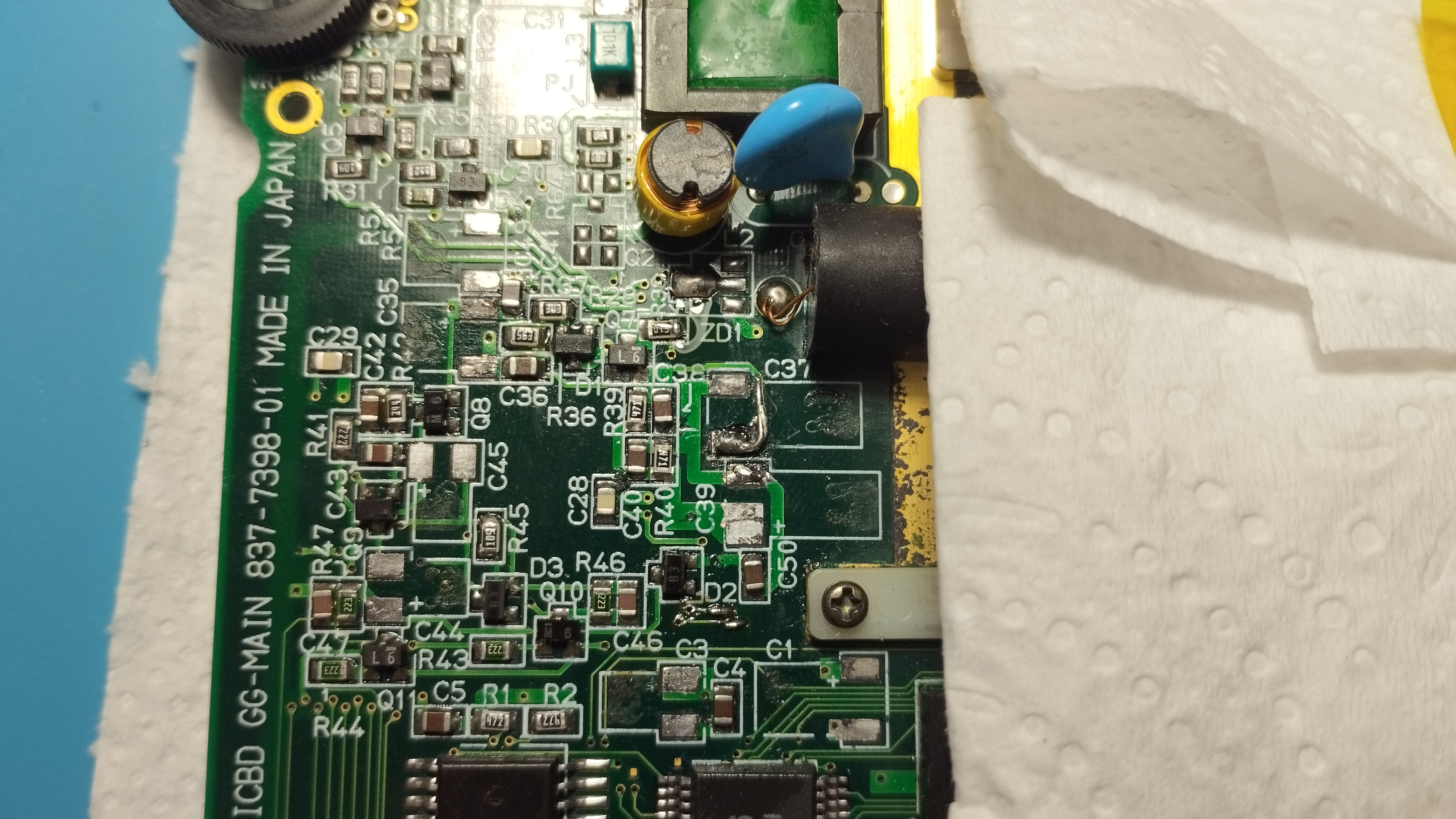

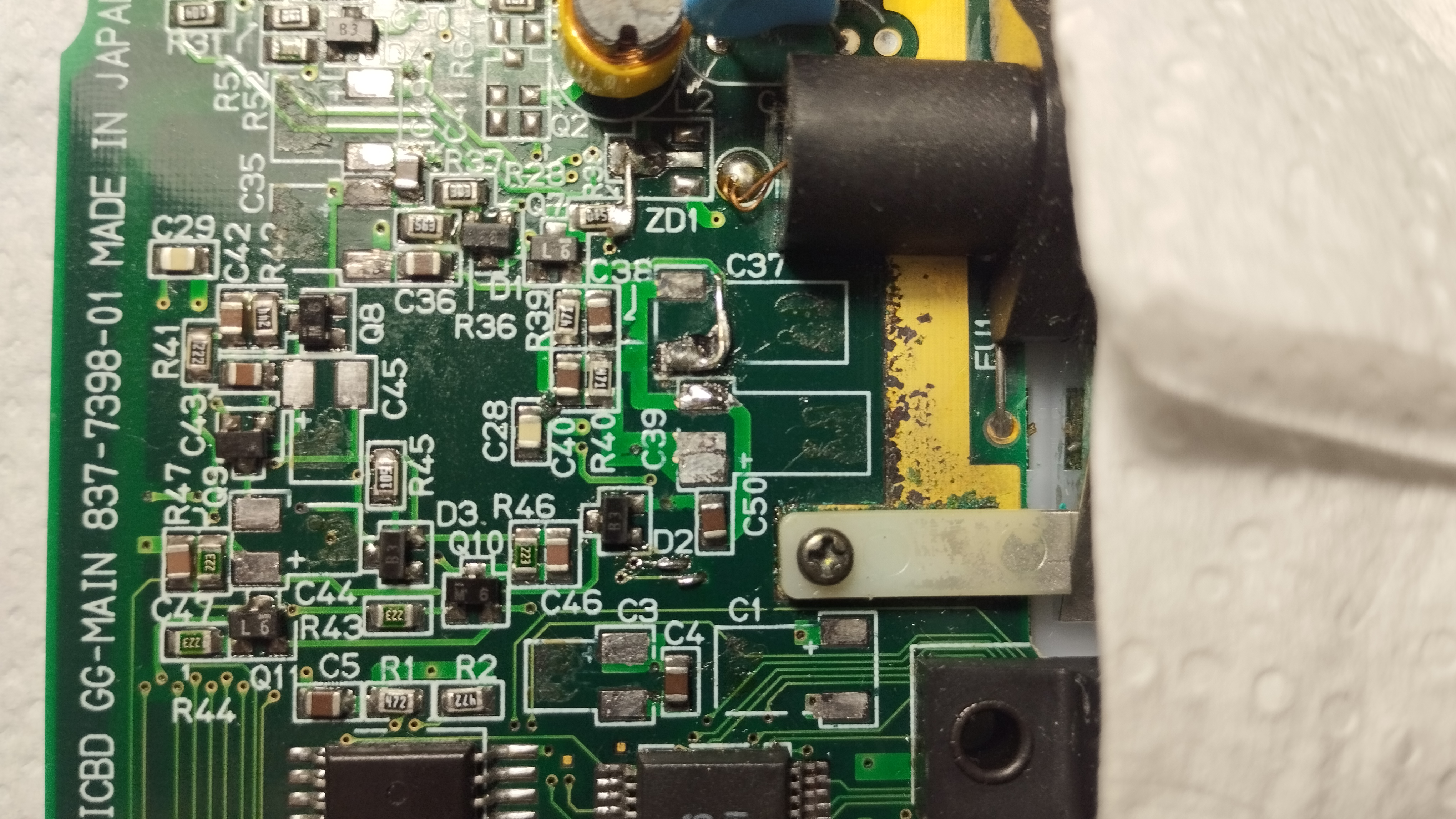

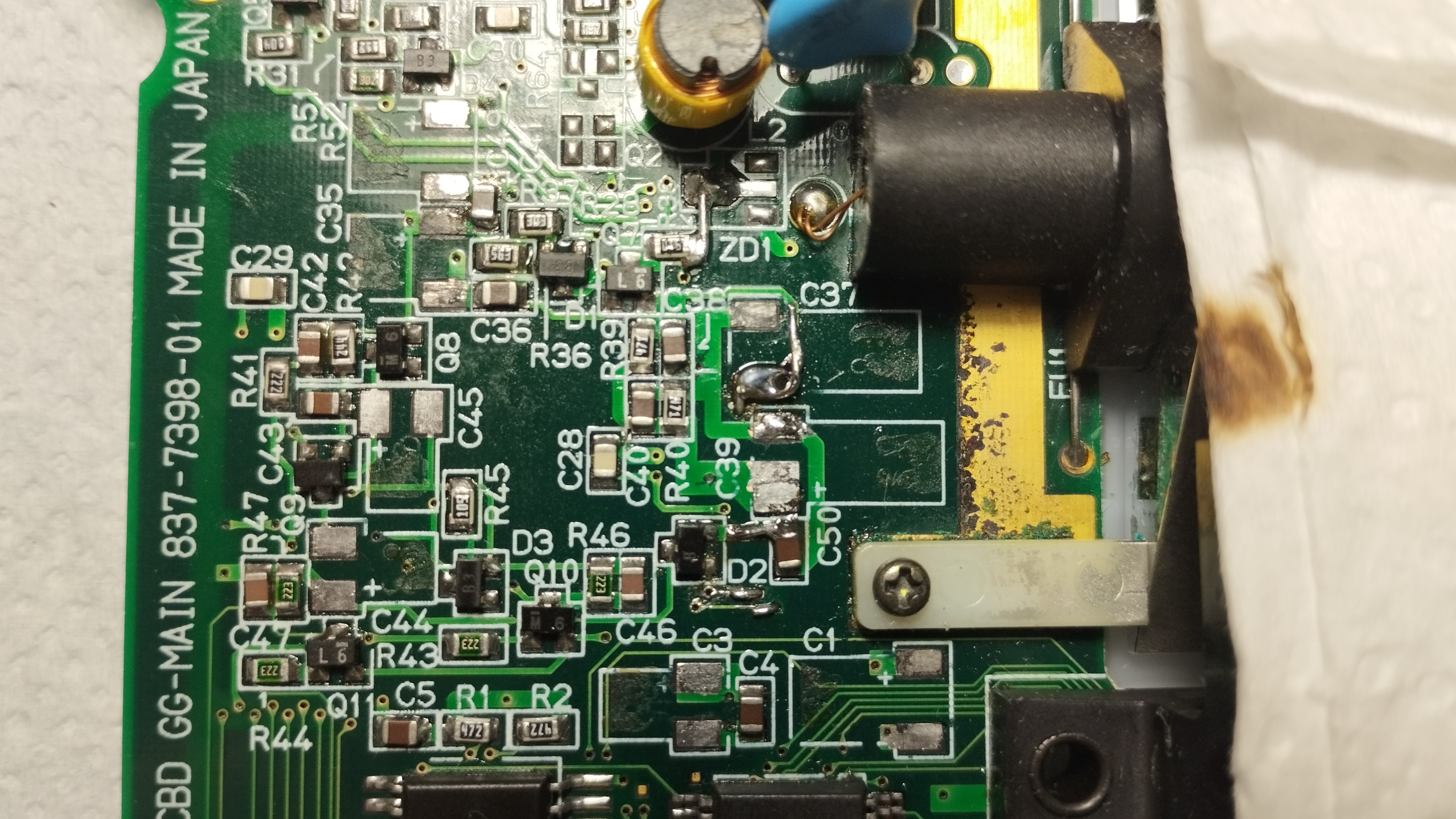

Mother Board - front view. Fixed connectivity of VOnOff below D2 - V5 network:

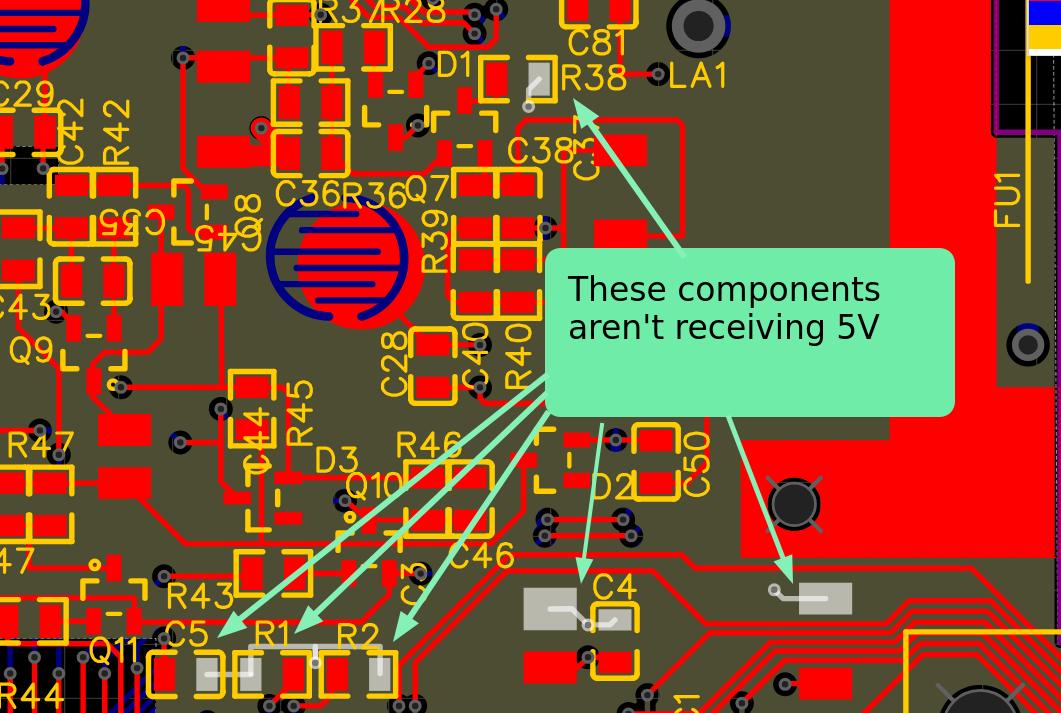

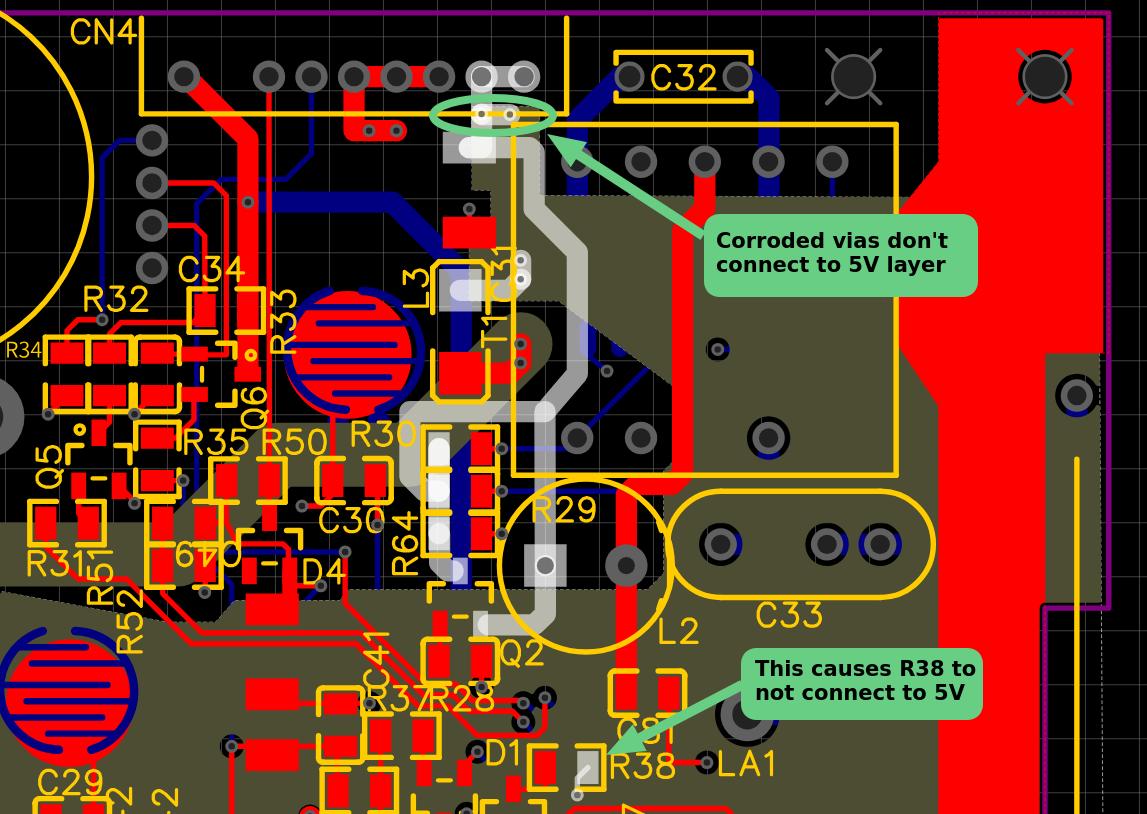

- ASIC isn’t receiving 5V, as well as other points

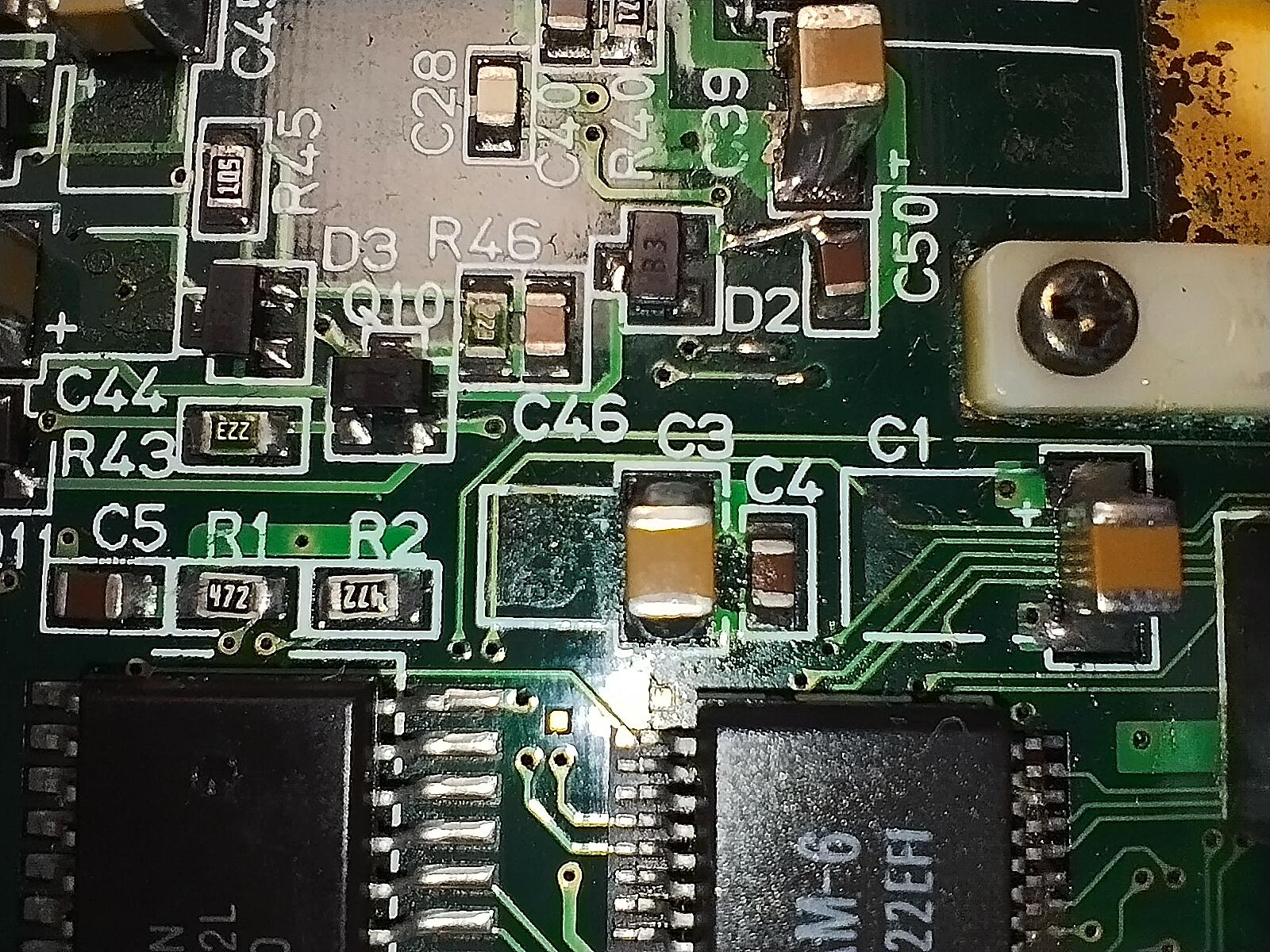

- R38, C1, C4, C5, R1, R2: according to EasyEDA schematics, they should receive 5V, but they don’t seem to be connected to the 5V plane:

EasyEDA - 2-ASIC schematic detail. Broken V5 continuity

Mother Board - Broken connectivity of V5 - Fixed by soldering unpopulated ZD1 5V pad to R38 right pad

Mother Board - Fixed connectivity of V5

This is properly detected and fixed later on as explained here. The procedure is kept for maintenance actions’ tracking.

- Other broken paths

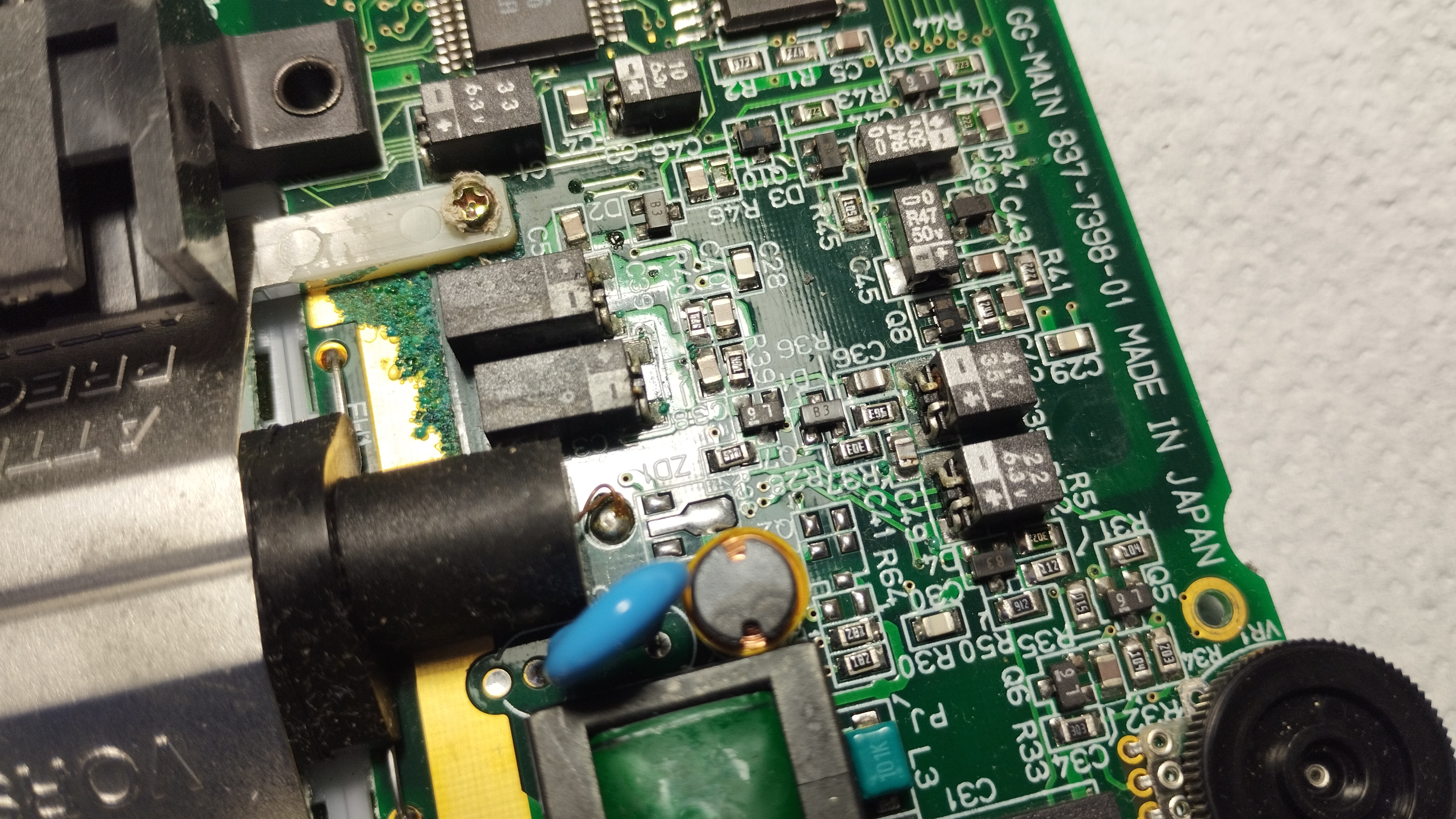

- Network R39_2 on EasyEDA: broken connection between C37 bottom pad and D2/C50 top pads –> Bottom layer trace isn’t connected to top layer

- Fixed by drilling small holes in the vias and reconstructing the bridge with a capacitor leg

Mother Board - rear view. Fixed connectivity of R39_2

Mother Board - front view. Fixed connectivity of R39_2

- Network R39_2 on EasyEDA: broken connection between C37 bottom pad and D2/C50 top pads –> Bottom layer trace isn’t connected to top layer

At this point, when powering up the console it now lights up the Power LED for a second

- VReset network:

- Network R51_1 on EasyEDA: broken connection between R35 left pad and VReset pin on ASIC –> Via next to D4 doesn’t connect both layers

- Fixed by drilling a small hole in the via and soldering a capacitor leg through it

Mother Board - rear view. Fixed connectivity of VReset next to D4

Mother Board - front view. Fixed connectivity of VReset next to D4

- Network R51_1 on EasyEDA: broken connection between R35 left pad and VReset pin on ASIC –> Via next to D4 doesn’t connect both layers

Here it seems that we reach the RLB state, even though sometimes it keeps turning down after a second

- Cartridge slot:

- Cartridge makes poor connection with the slot, being very difficult to reach a successful game boot

Either check the contacts or replace it

Testing the main board with a working audio board from another console we get sound from an inserted cartridge. At this point we can assure that the console works and we can proceed replacing the capacitors.

Once verified that the console reaches the RLB state, it’s time to solder the new capacitors. As with the previous VA-0 B0126683, these are the ceramic capacitors characteristics:

All original capacitors rated lower than 1uF are replaced with 1uF/50V ceramic capacitors

All original capacitors rated lower between 1uF and 10uF are replaced with 10uF/50V ceramic capacitors

All original capacitors rated higher than 10uF are replaced with 100uF/10V ceramic capacitors

Missing recapped board pictures!!

This time I didn’t use soldering paste because in the previous repair the result wasn’t cleaner enough for me and although there wasn’t shorts it seemed like the paste might create a bridge under the cap. The results are cleaner caps and brighter soldering points.

The soldering technique used this time consisted on the following steps:

- Tin one of the pads

- Pin one side of the capacitor to that pad

- After that apply solder to the other side

- Once done, rework the first pad by applying additional solder and adjusting the capacitor by applying heat to both pads if necessary

- Use a pair of tweezers to secure the capacitor in place while applying heat

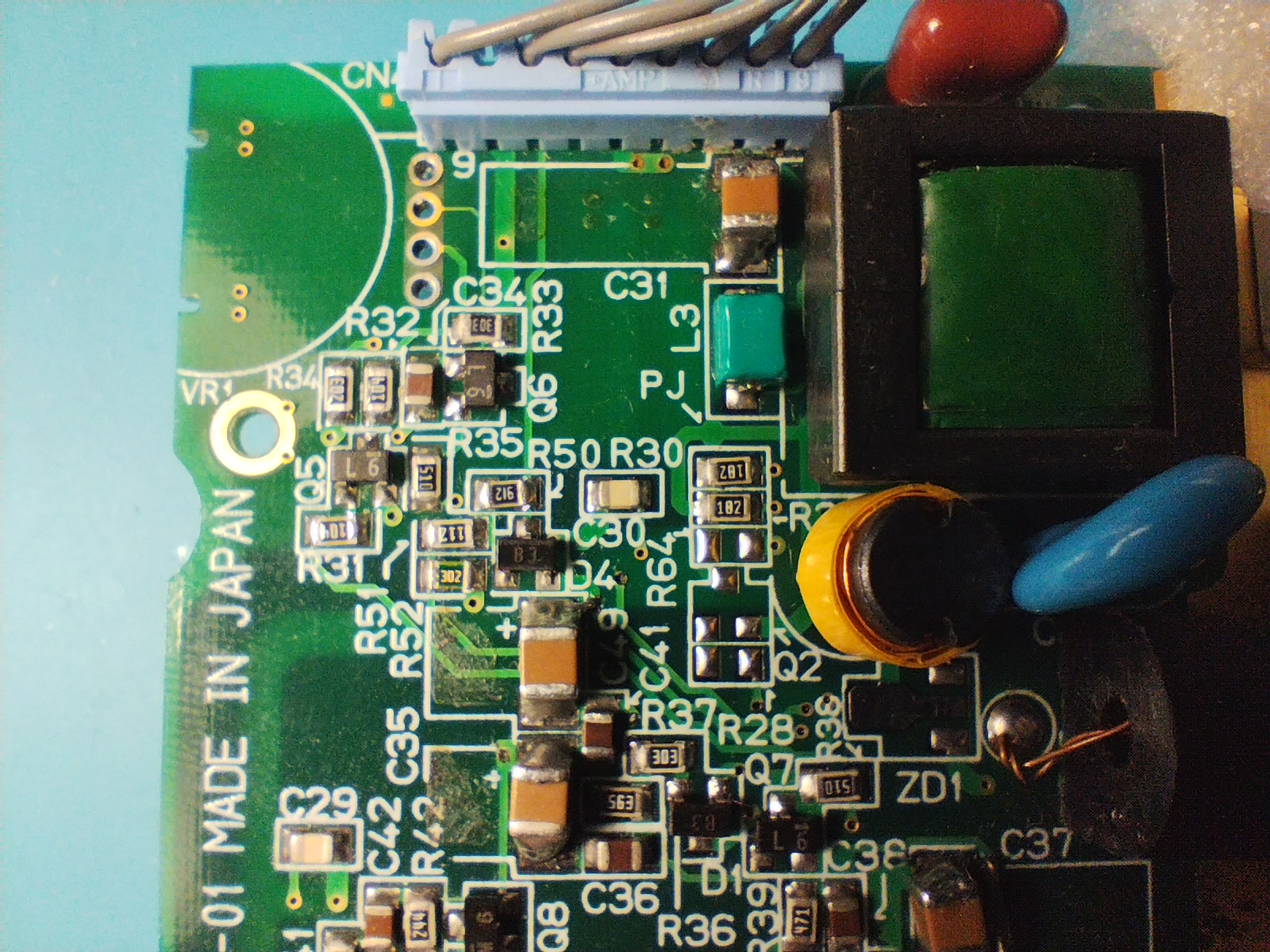

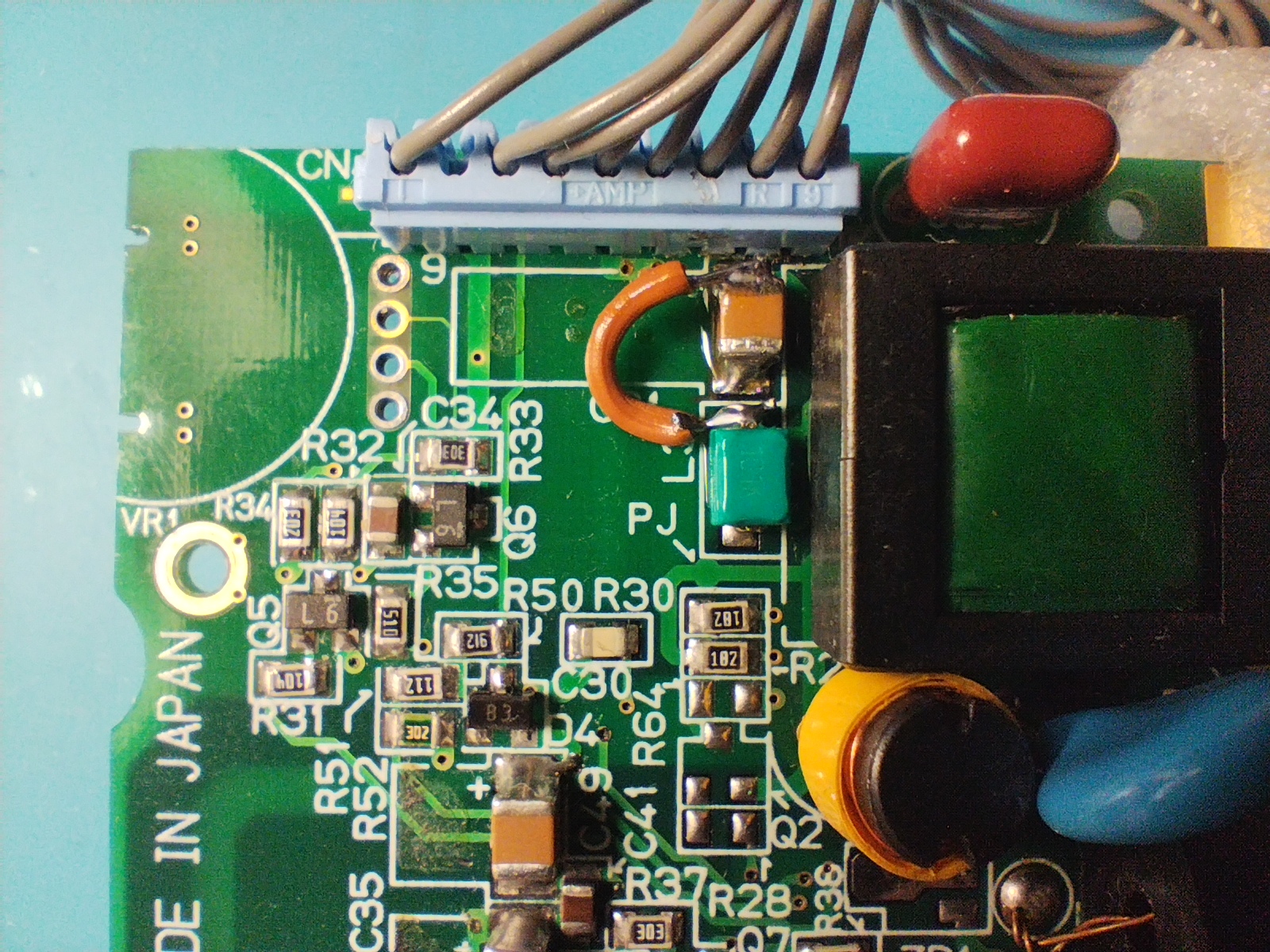

2024/06/24: Fixes on previous repairs

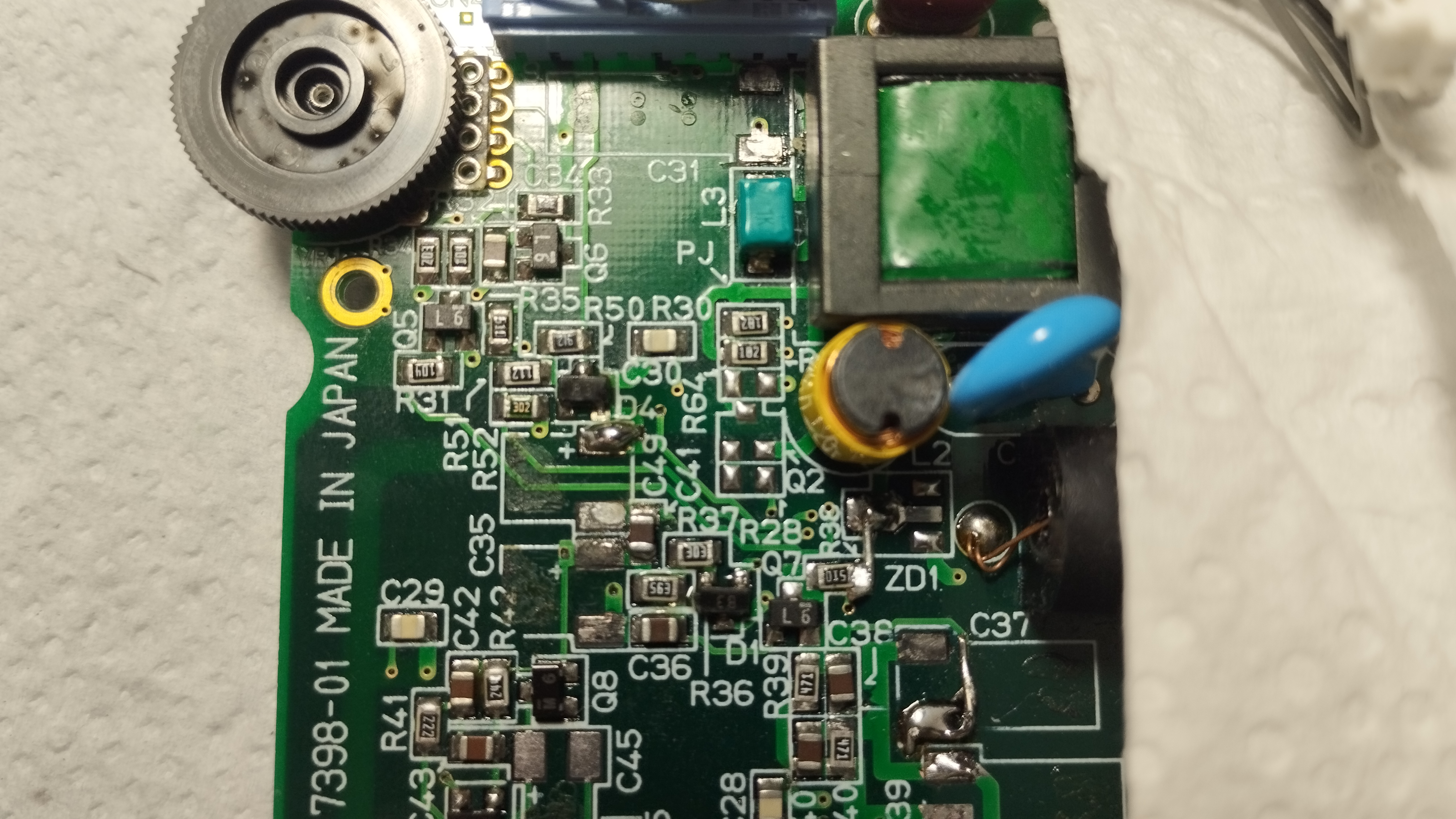

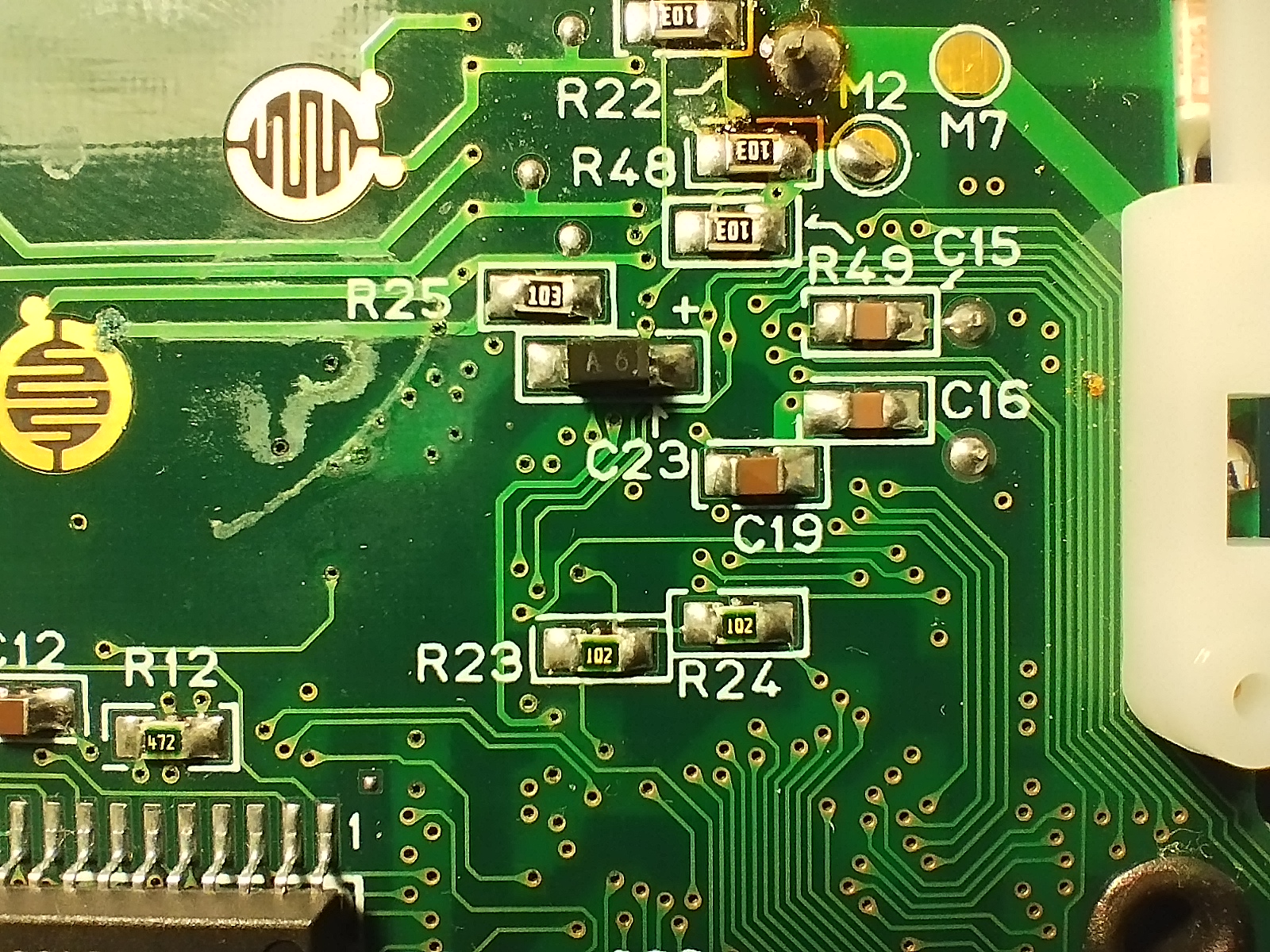

Bad fix for V5 network

On previous maintenance, a resistor leg between ZD1 and R38 right pad was soldered as shown here. This is incorrect as ZD1 is connected to the opposite side of the L2 inductor. In order to fix this:

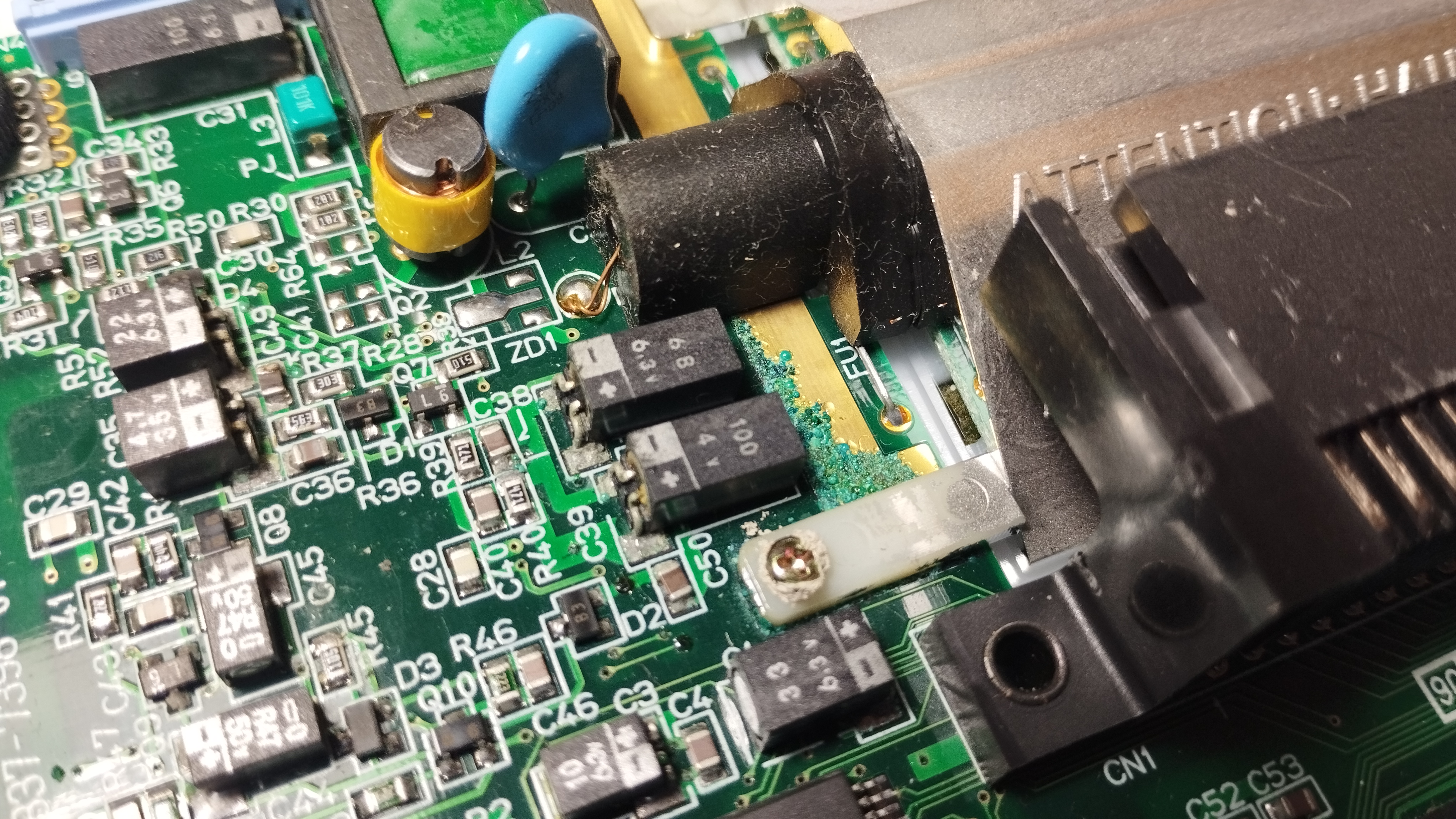

After further inspection, the failure point is located in the 5V vias underneath the power supply connector:

EasyEDA - 2-ASIC schematic detail. Failed 5V vias

Mother Board - Power connector. 5V vias corroded Current connection between ZD1 and R38 is removed:

Mother Board - Remove previous V5 fix V5 network properly fixed by connecting C31 upper pad and L3 upper pad:

Mother Board - Proper V5 network fix

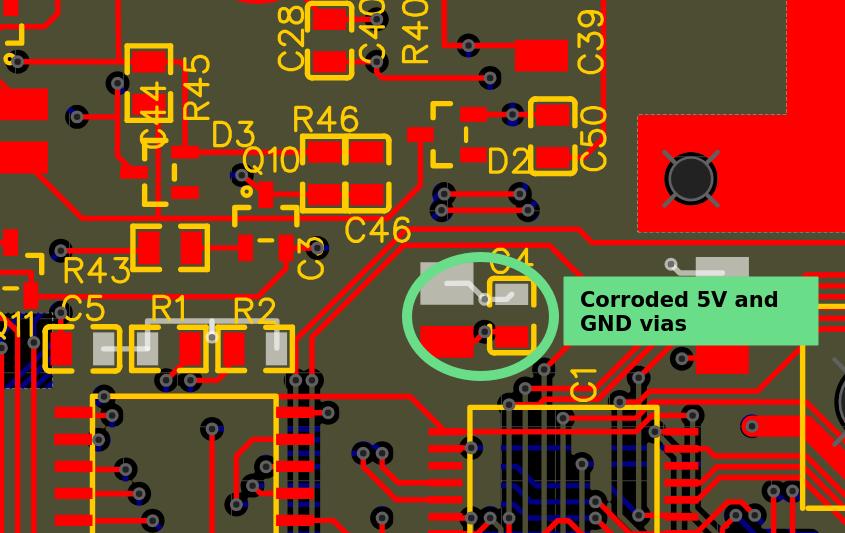

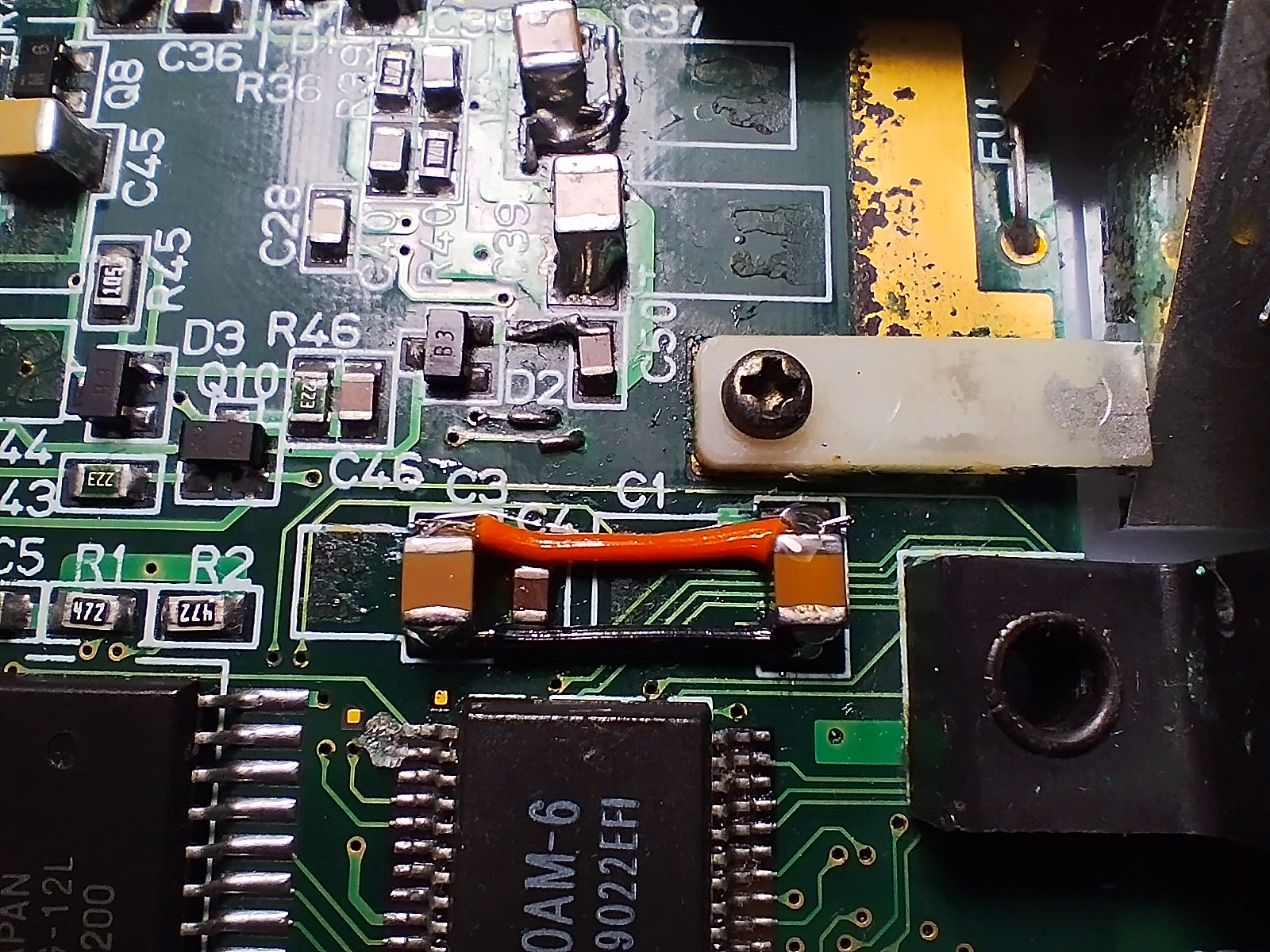

5V and ground fix for capacitor C3 and C4

Reviewing the 5V layer integrity, other components are found not being connected to it:

C3 and C4 are connected to 5V and GND through small vias:

EasyEDA - 2-ASIC schematic detail. C3 and C4 vias Proper testing shows that the vias are corroded and thus don’t connect neither to 5V nor GND:

Mother Board - C3 and C4 faulty connection to 5V and GND Fixing the vias is not an option, so pads are connected to C1 5V and GND:

Mother Board - C3 and C4 connected to C1

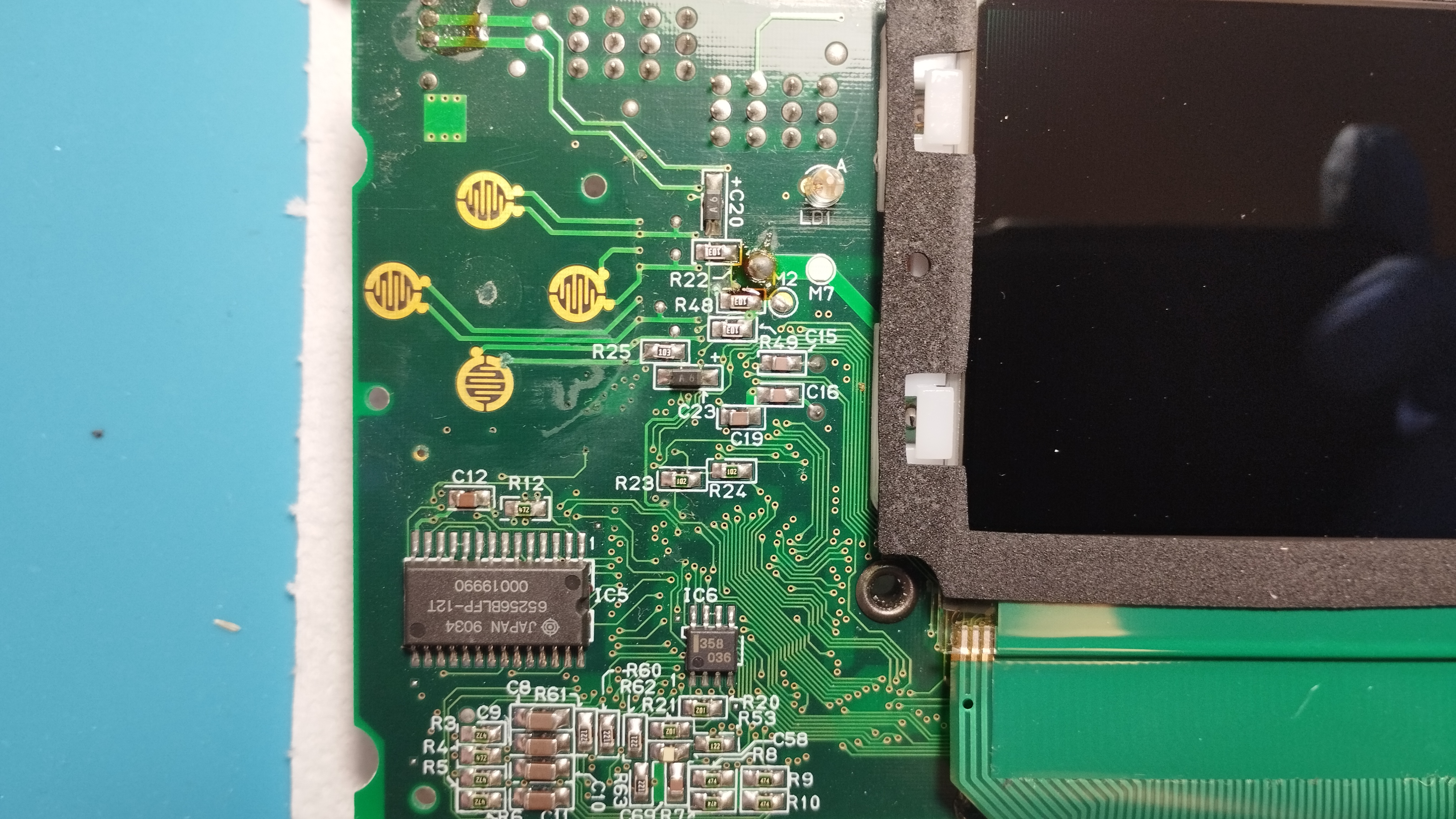

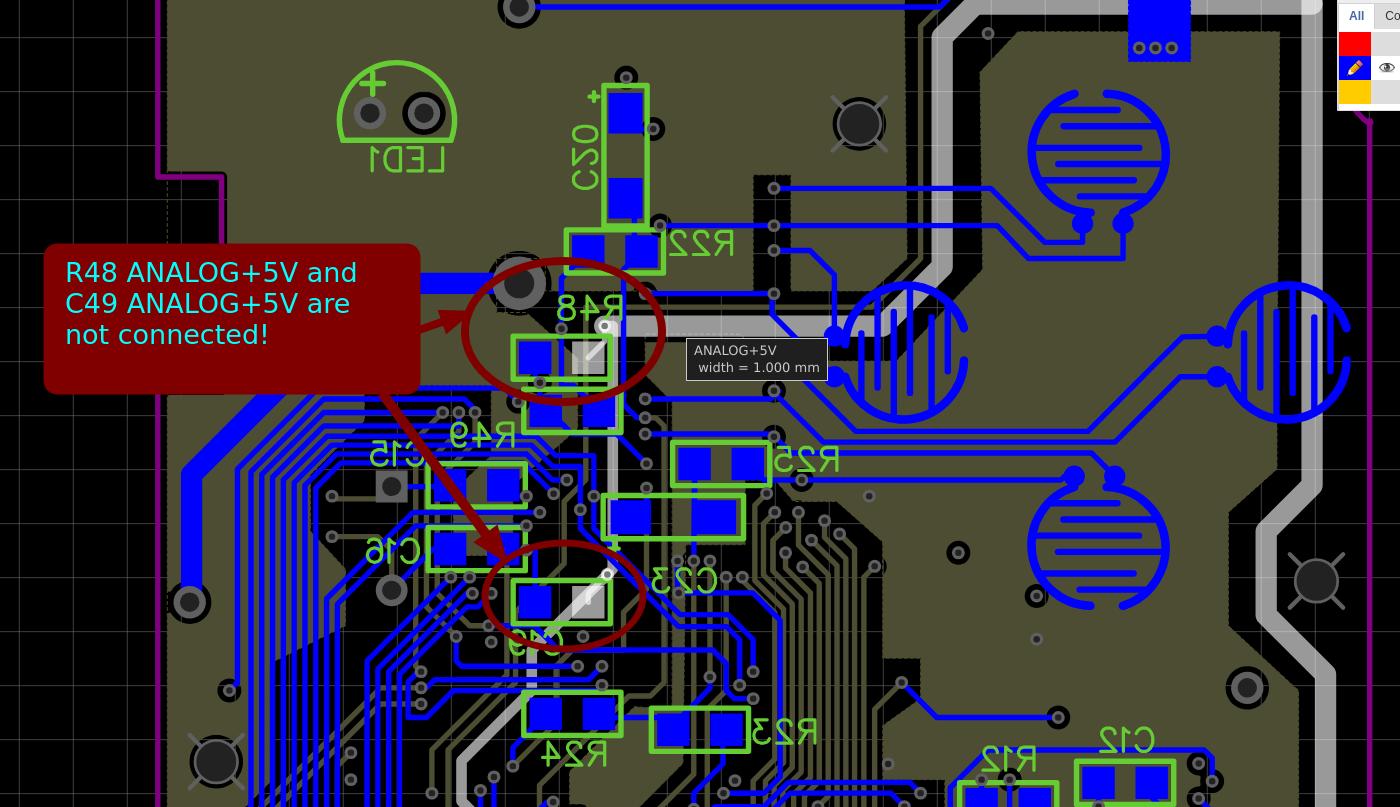

Analog 5V issues

The sound output on this board had too much noise even with properly repaired audio boards. A quick search Retrosix Discord channels mentioned that the issue might be with the Analog +5V and +2.5V paths.

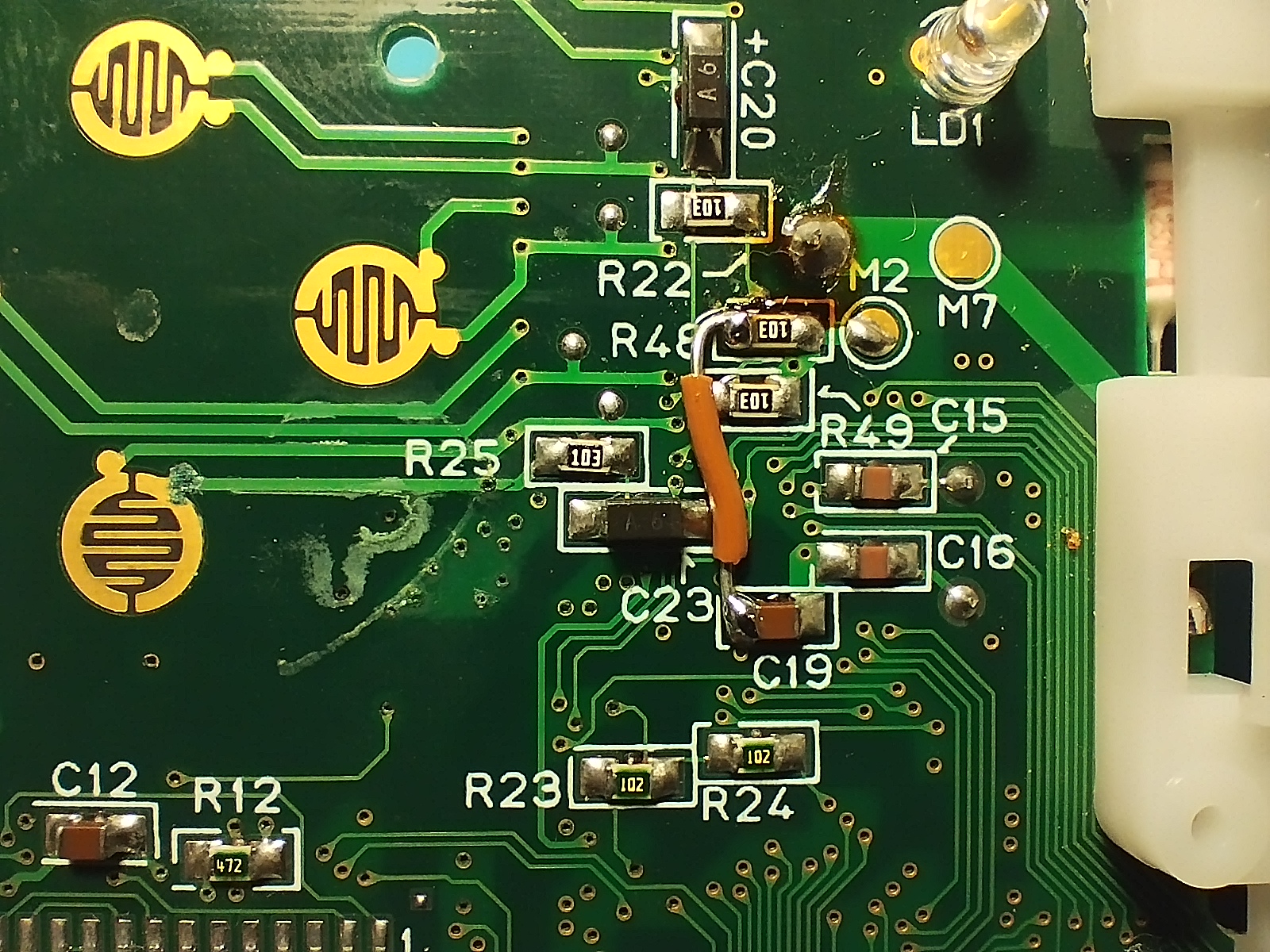

According to the schematics, a trace in the 5V layer connects R48 and C19 ANALOG+5V pads:

EasyEDA - 2-ASIC schematic detail. ANALOG+5V network Further testing shows that the vias are corroded and this connection is lost:

Mother Board - C19 faulty connection to ANALOG+5V Once again, fixing the via is not an option, so R48 and C19 pads are connected with a small wire:

Mother Board - C19 connection to ANALOG+5V fixed

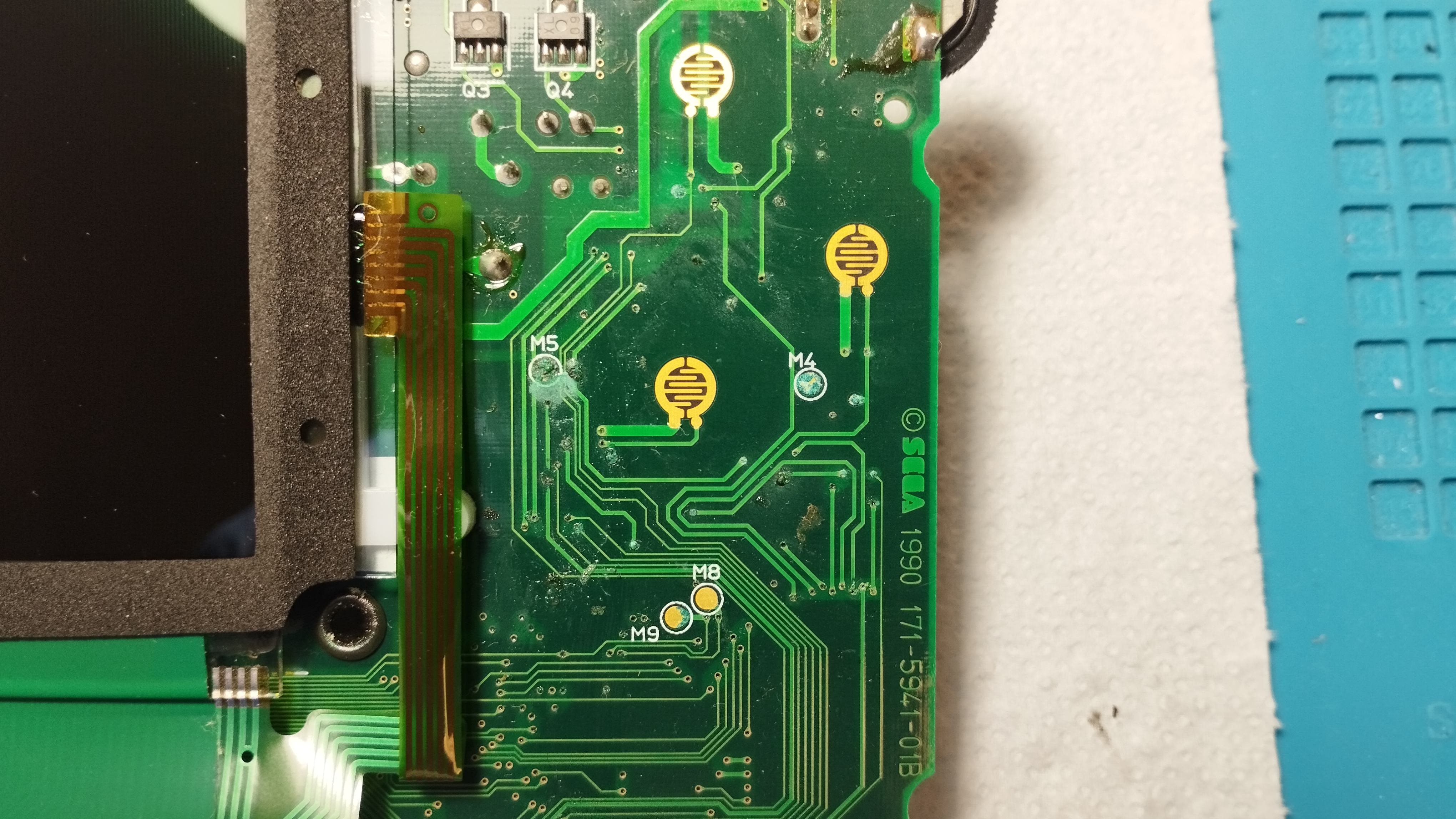

Cartridge slot contacts

Due to inconsistency when booting games, the cartridge pins have been resoldered to ensure proper contact. Now games boot at first try:

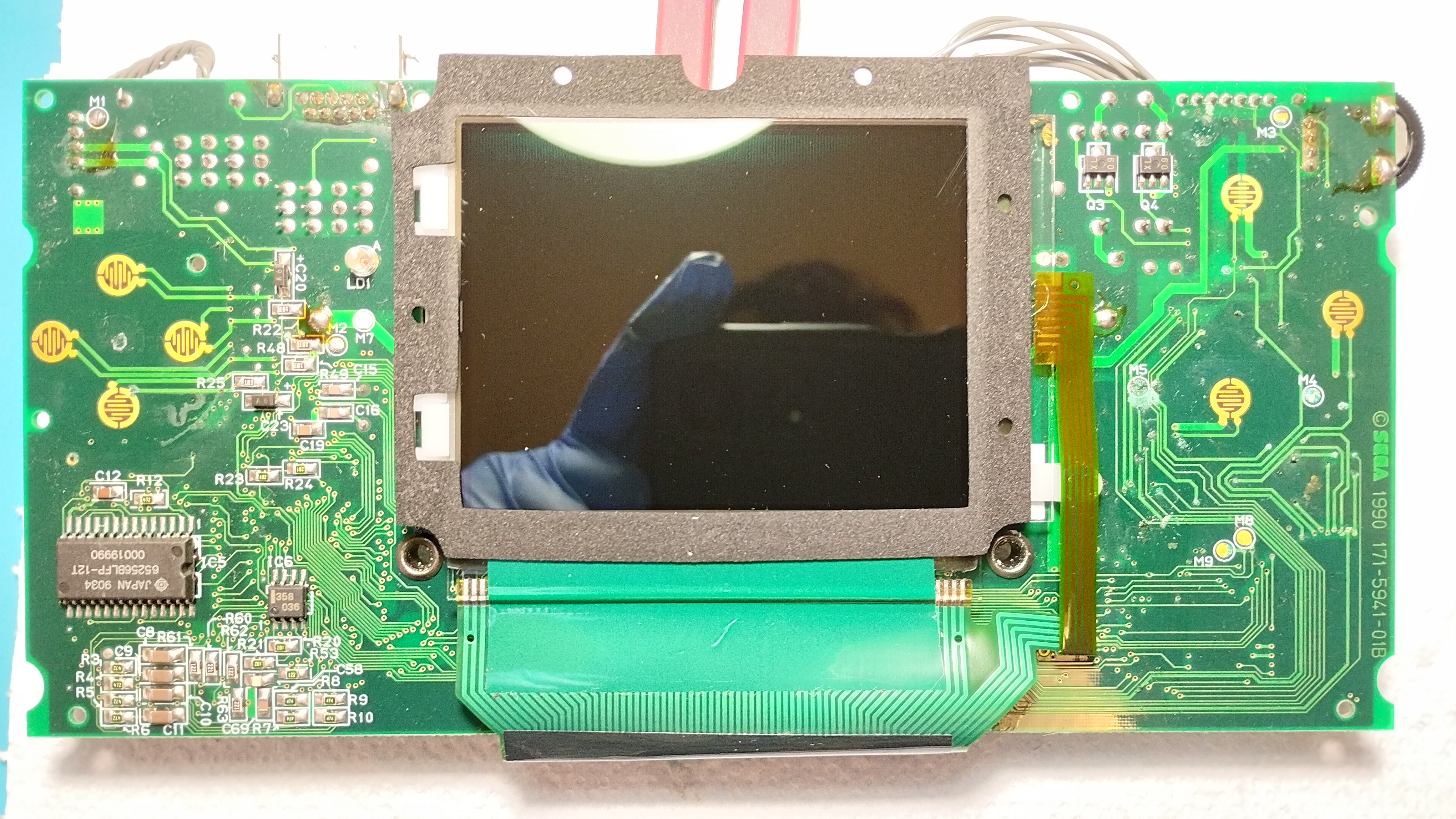

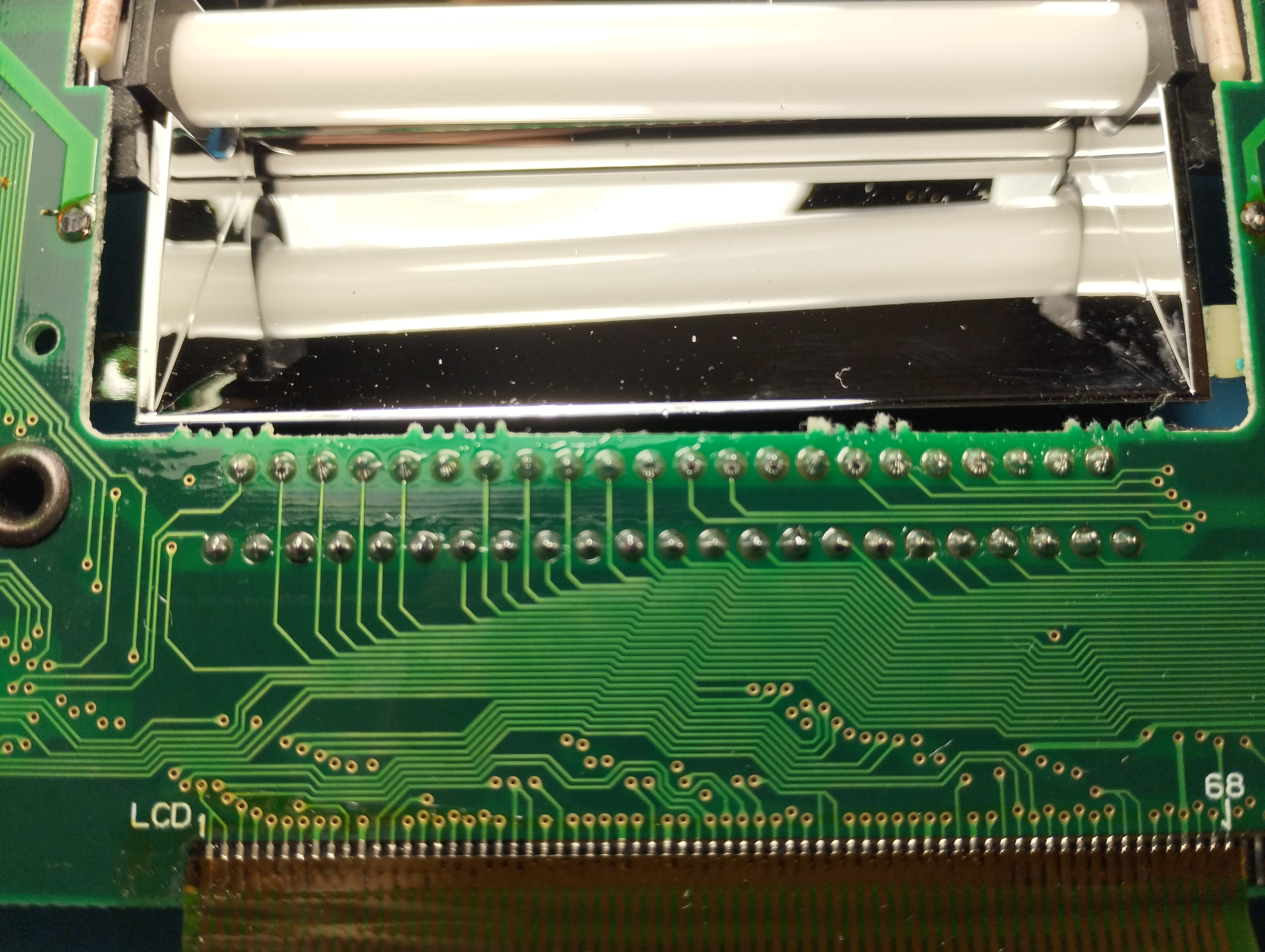

Screen swap

Original screen showed a dim image only when brightess wheel was set to a very specific position. Without an oscilloscope there’s no way to check if the video signals are correct. A screen swap with a spare one from unit 030011013 (not documented) where a BennVenn IPS screen mod was installed hasn’t solved anything, so the issue might still be in the main board.

The original screen is kept but not yet reinstalled.

Repairing time

- 11 hours 20 minutes

State on boot

- Console enters the Red Light Boot state, required for further troubleshooting and repairs

- Check of voltages is required

- Power board should be tested on other working units

- Audio board should be tested on other working units

- LCD turns on but image is very dim

- The fluorescent tube lights up but brightness wheel acts weird

- When tested with other working audio boards, game sound works

- Audio is very dim

It seems as if the recap didn’t make any effect at all

2024/06/22

Contrast wheel removed

- Donor piece for B0153410

2024/06/24

Repairing time

- 10 hours

Additional fixes

- Read from here for further details

Game operation at first boot

- Cartridge slot connection resoldered

Screen swap

- Current screen is from IPS-modded unit (030011013)

- Still not working

Next steps

Further checks on audio board

- Maybe capacitors aren’t correctly connected or there’s a broken path

Further checks on mother board

- Again, maybe some capacitor traces are broken or it’s just a non-functional screen

Even though the RLB state has been reached, the main board was very damaged due to corrosion and there might still be broken traces somewhere.